The construction industry accounts for over 4.5% of the nation’s Gross Domestic Product, which highlights its substantial impact on economic growth and stability. Every worker plays a crucial role in the construction of commercial and residential properties. The industry employs millions of people, and all face the same challenges to maintaining safety and well-being.

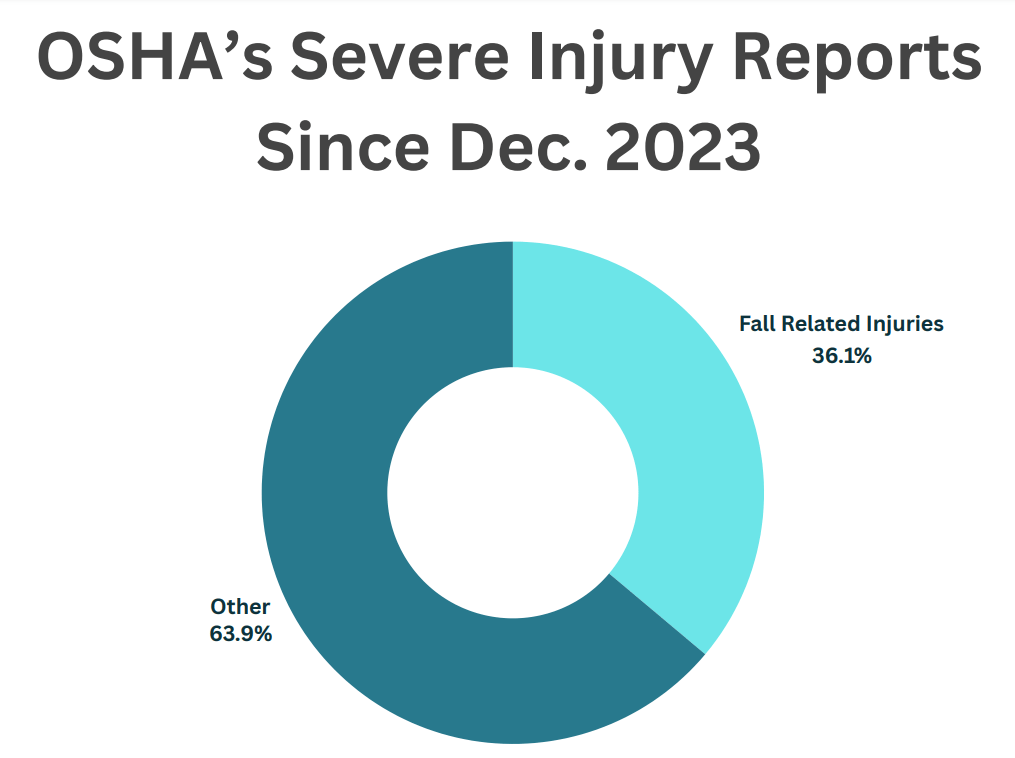

According to Occupational Safety and Health Administration (OSHA) rules, employers must report serious work injuries. This includes injuries that lead to going to the hospital or death.

As of December 2023, OSHA’s reports show that Falls are a leading cause of injuries and fatalities in the construction trade. The most common reasons people fall while working are lack of Fall Protection, Slippery Surfaces, and Lack of Training. As the weather changes and conditions become more challenging, it’s crucial to prioritize fall prevention.

Data Source: U.S. Department of Labor OSHA

Continue reading for some essential tips to keep construction workers safe and to give you the best idea on fall prevention for construction workers.

Stay Safe with the Proper Fall Equipment

Every construction employer should always invest in keeping their workers safe. They are your top assets driving your company; just like any assets, you want to protect them as best as possible.

- Harness – Ensure you use the correct-size harnesses, fit them properly, and inspect them regularly for damage or wear.

- Lanyards – Use lanyards that are appropriate for the job and are in good condition.

- Lifelines – Lifelines are synthetic fiber or steel wire rope lengths attached horizontally or vertically, and some can be retractable depending on the work task. Workers attach their lanyards to lifelines.

- Anchors – The most crucial step when mounting an anchor point is choosing a location. Ensure the anchor is high enough to prevent a worker from hitting a lower level, allowing you to do your job comfortably.

- Safety Net – Safety nets are helpful when performing constant, elevated work. They act as a barrier when fixed barriers or personal fall arrest systems are impractical. Ensure anchors can support the worker’s weight and are installed correctly.

Safe Work Practices

Plan Ahead

Assess the job site for potential fall hazards and develop a safe work plan. If you are constantly working at heights over 6 feet, refer to your company’s fall prevention plan. If your company does not have a fall protection plan, a good recommended resource would be OSHA’s fall prevention plan.

Maintain a Clean Work Area

When working at a construction site, we always try to multitask and complete tasks as quickly as possible. Because of that, we may lose sight of staying organized and leave our equipment for a short time.

Imagine a construction site with debris scattered on the floor. One worker steps on a loose piece of wood, causing them to trip and fall. The cluttered environment creates a tripping hazard, increasing the fall risk.

Employers can significantly reduce the risk of accidents and injuries by maintaining a clean and organized work area.

Use Warning Signs

In the construction industry, where hazards are abundant and constantly changing, warning signs are vital in ensuring worker safety. These signs clearly communicate potential dangers, such as open pits, electrical hazards, or falling objects. Construction companies can help prevent accidents, injuries, and fatalities by prominently displaying these signs in areas exposed to fall hazards. Compliance with safety regulations and appropriate warning signs are essential for creating a safe and productive work environment.

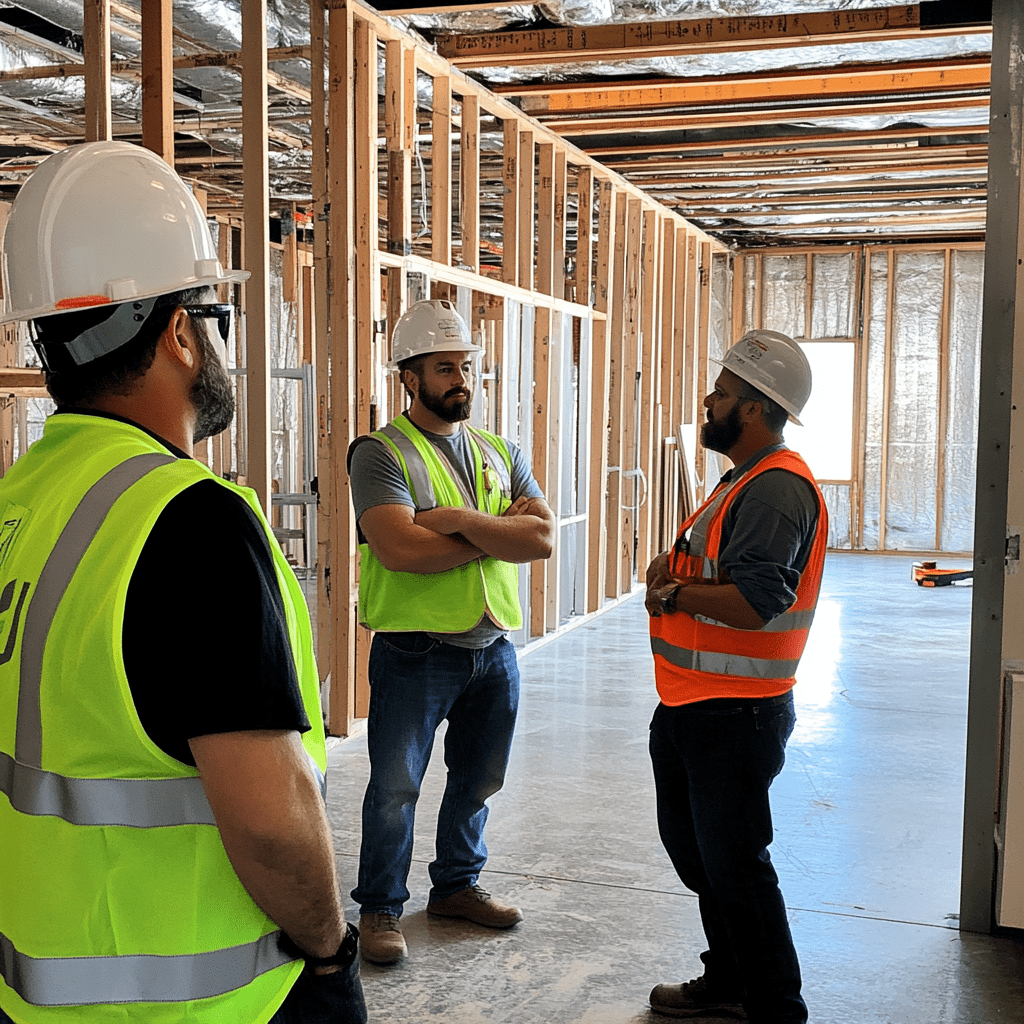

Fall Prevention Training

Regular Worker’s Training

Here at Fast Line Safety Training, we specialize in providing industry-standard training. Our Instructors are qualified to give you and your crew certification. You can visit our 8-Hour Fall Prevention course page, which includes in-depth scenarios and demonstrations to stay safe:

Complete Task Assessment

Ensure workers are competent in the use of fall protection equipment. If a job requires special equipment, do not believe you can complete a task faster by skipping on using safety gear. Consider every piece of work with extreme caution. When working in this industry, you can be injured by something as small as a stuck nail.

Choosing the Right Equipment

Choosing the right ladder for construction work is essential for safety and efficiency. The ladder’s type, size, and condition should be carefully considered based on the specific task and work environment. A sturdy extension ladder is often necessary for reaching higher levels, while a step ladder provides stability for shorter tasks. It is crucial to inspect ladders regularly for damage or wear and ensure they’re set up on a stable surface. Adhering to safety guidelines, such as maintaining three points of contact and avoiding electrical hazards, is paramount when using ladders in construction to prevent falls.

Emergency Procedures

Train workers on emergency procedures in case of a fall. Remember that you can break any bone from a fall of any height. It is essential to seek medical attention if you experience pain, swelling, or deformity after a fall, even if it seems minor.

Weather Consideration

Watch Out For Slippery Surfaces

The environment we work in doesn’t always cooperate. Therefore, we need to be more careful when this happens. The scaffolding platform surface is slipperier when working outside in the rain. For anyone who has experienced working in the winter, they have know that the worst conditions are to work on ice build-up. We recommend using non-slip sole footwear or OSHA-approved Ice Cleats to prevent this.

High Wind Advisory

Avoid working in high winds, as they can increase the risk of falls. Work involving cranes, scaffolding, or heights is generally more sensitive to high winds. A general rule of thumb is that construction work should be halted in winds exceeding 30-40 miles per hour.

Have Enough Lighting

Ensure adequate lighting is provided, especially during low-light conditions. Your work site should be able to see Caution signs and markings on the floor. Regarding floors, verify that your workers have a clear walking path to every part of the work area.

Final Thoughts

By following these essential fall prevention tips, construction workers can significantly reduce the risk of falls and injuries. Taking extra steps helps prevent workers from falling and company liability. Invest in high-quality fall protection for your construction workers. Remember, safety is a priority, and everyone has a role in creating a safe work environment.