Ladders are key for many tasks at home and work. But, they can be dangerous if not used right. Every year, thousands get hurt from ladder accidents, often because of wrong ladder choice, setup, or use. By following important ladder safety tips, you can lower the risk of accidents and injuries.

Using a ladder for home chores or on a construction site is risky. It’s vital to know how to stay safe. This means picking the right ladder, checking it before use, setting it up right, and climbing safely. Keeping your ladders in good shape and storing them properly is also crucial.

Key Takeaways

- Always select the appropriate ladder type and size for the task at hand

- Inspect ladders before each use to identify any damage or wear

- Set up ladders on stable, level surfaces away from electrical hazards

- Maintain three points of contact when climbing or descending ladders

- Follow OSHA regulations and standards for ladder safety in the workplace

- Regularly clean, lubricate, and properly store ladders to extend their lifespan

Understanding the Importance of Ladder Safety

Ladder safety is key for both home and work safety. Every year, thousands get hurt from ladder accidents. These injuries range from small bruises to serious fractures and even death.

Common reasons for ladder accidents include setting up ladders wrong, reaching too far, using the wrong ladder, and not keeping three points of contact. These accidents cause physical harm, lost work time, higher healthcare costs, and emotional pain for victims and their families.

During the holiday season, ladder safety is even more critical. Many people use ladders to hang Christmas lights and decorations. The Consumer Product Safety Commission says there are about 15,000 holiday decorating injuries each year. Falls from ladders are a big part of these incidents.

| Ladder Accident Statistic | Annual Occurrences in the United States |

| Ladder-related deaths | 300+ |

| Emergency room cisits due to ladder accidents | 130,000+ |

| Holiday decorating-related injuries | 15,000 |

To avoid ladder accidents, safety awareness and proper ladder use are crucial. Choose the right ladder for the job, check the ladder before use, and place it on a stable surface. Always keep three points of contact while climbing or going down. Following these steps can greatly lower the risk of ladder accidents.

" Ladder safety is not just about following the rules; it's about valuing your life and the lives of those around you. "

Both employers and employees must see the value in ladder safety training. By promoting a safety culture and offering ongoing education, workplaces can reduce ladder accidents. This makes the work environment safer for everyone.

Choosing the Right Ladder for the Job

Ladder Types and Materials

Ladders are made for different jobs. Here are the main types:

- Step ladders: Great for indoor use and stable tasks.

- Extension ladders: Adjustable for high places, needing support.

- Multi-position ladders: Can be used in many ways, like step or extension ladders.

- Aluminum: Light, durable, and rust-free.

- Fiberglass: Safe near electricity, strong, and non-conductive.

- Wood: Affordable, stable, but needs upkeep to last.

Weight Capacity and height Considerations

Think about the job’s weight and height needs. Ladders have weight limits, including what you carry. Pick one that can handle more than you need for safety.

The ladder’s height must match the job. Don’t reach too far or stand on the top. The ladder should be at least three feet above where you land to be safe.

Choosing the right ladder for your job reduces accidents. It makes your work area safer and more efficient.

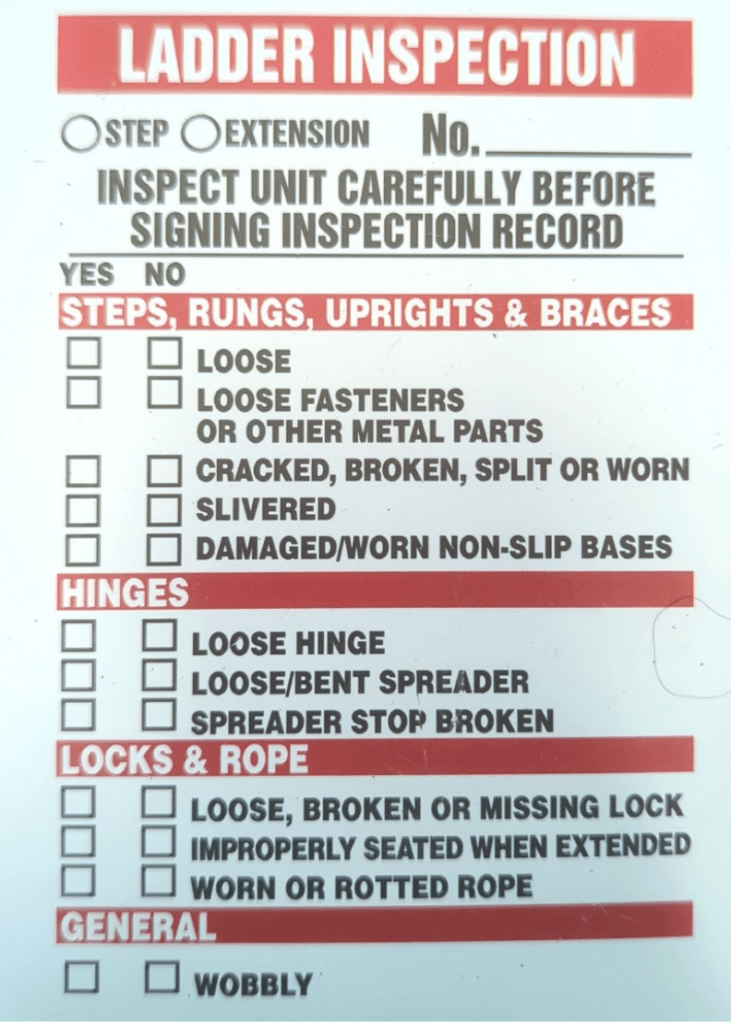

Pre-Use Ladder Inspection

Before you use a ladder, it’s key to check it over carefully. This ensures it;s safe and works right. Here’s how to inspect your ladder:

Identifying Damage and Wear

Look for any damage or wear on the ladder. Check for:

- Cracks, splits, or breaks in the side rails or rungs

- Bent or dented parts

- Corrosion or rust on metal parts

- Loose or missing rivets, screws, or bolts

- Worn or frayed ropes on extension ladders

If you find any damage, don’t use the ladder. Get it fixed or replaced instead.

Safe Ladder setup and Placement

Setting up your ladder correctly is key for a safe work area. Before starting, make sure your ladder is placed and secured right. This helps avoid accidents and injuries.

Stable and Level Surface

Always put your ladder on a solid, level ground. It should hold the ladder’s weight and yours. Don’t set up ladders on wet grass, loose gravel, or uneven areas. Use a leveling device or stabilizer if needed for a stable base.

Proper Angle and Distance from Wall

Position your ladder at the right angle for stability. The best angle is 75.5 degrees. To find this, use the “4-to-1” rule: for every 4 feet of ladder height, stand 1 foot away from the wall.

" The 4-to-1 rule is a simple and effective way to ensure your ladder is positioned at the safest angle for climbing and descending. "

Avoiding Electrical Hazards

Be careful with electrical safety when setting up your ladder. Keep ladders at least 10 feet away from power lines and electrical gear. Use a non-conductive ladder, like one made of fiberglass, near electrical sources to avoid electrocution.

By following these safe ladder setup and placement tips, you can make a secure work area. This reduces the chance of accidents and injuries.

Climbing and Descending Techniques

Learning how to climb and descend ladders safely is key to staying safe at heights. By using the right techniques, you can lower your chances of getting hurt. Always remember, slow and steady is the best way to stay safe on ladders.

When you’re climbing a ladder, always face it and keep three points of contact. This means having two hands and one foot, or two feet and one hand, on the ladder. Don’t carry tools or materials in your hands. Instead, use a tool belt or have someone hand them to you.

Stay centered between the side rails as you go up or down the ladder. Don’t lean too far to one side, as this can make the ladder unstable. Move slowly and deliberately, avoiding sudden movements that could throw you off balance.

" ladder safety is not a destination, but a continuous journey of awareness, preparation, and practice. "

When it’s time to go down the ladder, face the ladder, keep three points of contact, and move slowly. Don’t rush or skip rungs, as this can lead to slips and falls.

Maintaining Three Points of Contact

Keeping three points of contact is key to ladder safety. This means having two hands and one foot, or two feet and one hand, on the ladder. Following this rule helps prevent falls by keeping you balanced.

Proper Hand and Foot Placement

It’s important to place your hands and feet correctly on the ladder. When climbing, put your hands on the rungs or side rails at shoulder level. Your feet should be centered on the rungs, with toes pointing forward.

Don’t grip the ladder too hard. This can cause fatigue and make it harder to control.

Here are some tips for proper placement:

- Place your hands on the rungs or side rails

- Grip the ladder firmly but not too tightly

- Keep your feet centered on the rungs, with your heels against the back of the step

- Wear slip-resistant shoes with good traction

Avoiding Overreaching

Overreaching is a major cause of ladder accidents. It happens when you stretch too far to the side or reach above your head. To avoid this, follow these guidelines:

| Do | Don't |

| keep your body centered between the side rails | Lean too far to the side |

| Move the ladder when you need to reach a new area | Stretch to reach something beyond your arm's length |

| Maintain three points of contact while reaching | Stand on the top rung or step |

Remember, “An ounce of prevention is worth a pound of cure.” By keeping three points of contact, placing your hands and feet right, and avoiding overreaching, you can greatly lower the risk of ladder accidents. This ensures a safe climbing experience.

Ladder Safety in the Workplace

Keeping the workplace safe from ladder accidents is a big job for both bosses and workers. By following OSHA ladder regulations and training well, companies can lower the chance of ladder accidents and injuries.

OSHA Regulations and Standards

The Occupational Safety and Health Administration (OSHA) has set clear rules for ladder safety. These rules cover how to pick, check, and use ladders. Bosses need to know these rules and follow them to keep their workplace safe.

Employer Responsibilities

Employer responsibilities go beyond just having ladders. They must make sure ladders are safe, right for the job, and used right. They should check ladders often and fix any problems. They also need to give workers the right safety gear and teach them how to use ladders safely.

Employee Training and Awarness

Good employee training is key to keeping ladders safe. Bosses should teach workers how to pick, set up, and use ladders correctly. This includes knowing hazards, keeping three points of contact, and not reaching too far. By teaching workers well, companies can make their workplaces safer.

Ensure the safety of your employees by signing up for our comprehensive ladder safety training program. Our expert instructors will teach your team the essential skills and knowledge to safely use ladders in a variety of work environments. From proper inspection techniques to safe climbing and descending practices, our 2 hr course covers everything your employees need to know to prevent accidents and injuries.

Fast Line Safety Training Course:

" Ladder Safety is a shared responsibility. By working together and prioritizing training and compliance, employers and employers can create a safer work environment for everyone. "

Putting effort into ladder safety helps keep workers safe and shows a company cares about them. By following OSHA rules, doing their jobs, and training workers well, companies can make their workplaces safer and more productive.

Ladder Maintenance and Storage

Keeping your ladders in good shape is key for safety and longevity. Regular cleaning and lubrication, along with proper storage, prevent accidents. This also extends your ladders’ life.

Regular Cleaning and Lubrication

It’s crucial to clean your ladders often. Get rid of dirt, grease, and other stuff that builds up. Use a mild soap and water mix to clean, then dry it well to stop rust.

For moving parts like hinges and locks, use a silicone-based lubricant. This keeps them working smoothly and prevents them from sticking.

Here’s a simple cleaning and lubrication schedule to follow:

| Frequency | Task |

| After each use | Wipe down the ladder to remove dirt and debris |

| Monthly | Clean the Ladder thoroughly with a mild detergent and water solution |

| Quarterly | Lubricate moving parts with a silicone-based lubricant3 |

Proper Storage Techniques

Hang them horizontally on wall racks or store them vertically against a wall. Don’t store them near heat or chemicals that can harm the materials.

" A well-maintained ladder is a safe ladder. Take the time to clean, lubricate, and store your ladders properly to ensure their longevity and your safety."

By following these easy tips, you can keep your ladders in great shape. This reduces the chance of accidents at home or work.

Common Ladder Hazards and How to Avoid Them

Using ladders can be risky if you don’t know the hazards. Knowing these dangers and taking safety steps can help avoid accidents. This keeps you and others safe.

Unstable or Slippery Surfaces

Setting up ladders on unstable or slippery surfaces is a big risk. Make sure the ground is level, firm, and clear of debris or liquids. This prevents the ladder from slipping or shifting.

If you’re on soft ground like soil or grass, use a ladder with wide, non-slip feet. Or place a sturdy board under the ladder for extra stability.

Overloading and Exceeding Weight Limits

Every ladder has a weight limit that must not be crossed. Overloading can make the ladder buckle, break, or tip over, leading to serious injuries. Before climbing, check the ladder’s weight limit.

Make sure the total weight of you and any tools or materials doesn’t exceed this limit. Spread the weight evenly on the ladder. Avoid putting heavy items on one side, as it can make the ladder unstable.

Electrical Hazards and Power Lines

Be careful with electrical hazards, especially overhead power lines, when using ladders. Always keep a safe distance from power lines. Never use a metal ladder near electrical sources.

If you must work near electricity, use a non-conductive ladder made of fiberglass or wood. Also, avoid using ladders in wet or damp conditions to prevent electrical shock.

How often should I insspect my ladder my ladder for safety?

Always check my ladder before using it. Look for damage, wear, or missing parts. These can affect its safety and stability.

What should I consider when selecting a ladder for a specific job?

Think about the ladder type, material, weight capacity, and height needed. Choose one that fits the job and keeps you safe.

How can I ensure my ladder is set up safely?

Place the ladder on a stable, level surface. Follow the angle rule and avoid electrical hazards. Always follow the manufacturer’s instructions for safety.