16 Hour Rigging Worker

Course Duration

16 Hours

Course Session

2 – 3 Session

Language

English, Spanish

Training Type

Classroom Training

Course Overview

The 16-Hour Rigging Course prepares workers to perform rigging, and signaling construction work, while hoisting and lowering materials along the outside of a building. The Rigging Class shows participants the proper way to operate rigging equipment, and how to protect themselves and others around them. Workers will also receive a review of OSHA policies, ASME, and DOB regulations with an emphasis on the recognition and prevention of potential hazards.

Other topics of this rigging safety training will include instructions on how to visually inspect rigging equipment, basic crane components, crane setup and methods of applying proper rigging hitches.

Fast Line Safety Training delivers high-quality, hands-on training at your location and provides the industry’s preferred operator card.

Additional Course Information

What you'll learn

- Develop an understanding of rigging principles and practices

- Gain in-depth knowledge of rigging equipment and its safe operation

- Enhance safety awareness and hazard recognition

- Master load planning and execution

- Acquire practical skills through hands-on training

CEU Credits Earned

1.6

Continuous Education Units

Need to renew your 16 hour Rigging Worker?

You may need to renew your 16-Hour Rigging Worker certification if:

- Your current certification has expired

- Your employer requires it;

- Industry standards or regulations have changed

- If you feel that your skills need a refresher

Learning Outcomes

Upon completion of this course, students should be able to:

- Inspect rigging equipment under OSHA, ASME, and the manufacturer’s requirements

- Identify potential rigging hazards or faulty equipment

- Identify hitch configurations, equipment capacities, and basic knots

- How to use rigging equipment and hitches in various applications

Interested in becoming a Rigging Worker?

As per 3316.9.2.1 of the 2014 NYC Construction Codes, this course is required by the NYC Department of Buildings for individuals not hired directly by a person holding valid rigging certification who attach or detach articles from the hook of hoisting equipment and signal persons communicating with such in New York City.

Course Outline

This Course outline provides a general overview of the topics to be covered. The actual course content may be adjusted slightly based on the specific needs and learning styles of the participants

Lesson 1: Introduction to Rigging

- Inspection

- Maintenance

- Repair

- Use and installation of rigging equipment

- Hazards associated with rigging

- The relevant sections of the building code and industry

practice with regard to rigging. - The definition of rigging and the traditional uses for rigging

in the construction environment, including:- material hoisting

- suspended scaffolds

- industrial rope access (IRA)

- Emphasize that this course focuses on material hoisting

- additional training is required for suspended scaffolds and

IRA work

- additional training is required for suspended scaffolds and

Lesson 2: Crane & Rigging Accidents

- Common causes of accidents with cranes

- Historical crane accidents in NYC and other major cities

- Overview of rigging incident statistics for the most current

24-month period:

- Failure; injury; death

- Close review of two failure scenarios with emphasis on what went wrong and how the incident could have been prevented

Lesson 3: CFR 29 OSHA 1926 Overview

- Subparts:

- M (Fall Protection)

- CC (Cranes and Derricks in Construction)

Lesson 4: NYC COnstruction Codes Overview

- Code

- Rules

- Relates Department policy statements

- Regulatory notices, bulletins and memos, including:

- 2022 Building Code

- Chapter 33

- 1 RCNY 3316-01 & RCNY 3319-01

Lesson 5: NYC Department of Buildings

- Administrative standard operating procedures

- Policy procedure notices

- Permits/Department notifications

- Forms

- Filing and site Documents

- Plans

- Inspection checklists/logs

- Wind and Weather advisories

Lesson 6: Lifting & Lowering Load

- Overview of general practices involved with hoisting:

- Steel

- Concrete buckets

- Rebar

- Masonry

- Curtain walls

- Similar items commonly hoisted during construction

- Maneuvering and drifting loads

- Hazards of:

- Operating in a dense urban environment

- High winds

- Effects of wind on rigging

- Operating near power lines

- Prohibition against hoisting over:

- Pedestrians

- Traffic

- Adjoining buildings

- Overhead protection/safety exclusion zones during rigging

- Hazard signage for:

- Sidewalk sheds

- Barriers

- Flag persons

- Requirements for guardrails and safety netting

- Securing rigging platforms during the day and at the end of the shift

- When a licensed rigger or rigging foreman is required

- When a critical pick plan is required

Lesson 7: Ropes, Knots & Hitches Overview

- Common types of ropes (wire and fiber)

- Grades of rope and their application

- Handling of ropes

- Common knots and hitches and their application

- Rope and knot strength

- How hitches and angles impact rope strength

- Review of manufactures’ specifications and limitations

for ropes

Lesson 8: Riggin Equipment Overview

Overview of common types of rigging equipment, their

use, handling, strength, and application, including:

- Fasteners

- Hooks

- Shackles

- Thimbles

- Eyes

- Other connections & termination of ropes

- Tackle blocks

- Slings

- Come-along

- Pulleys

- Chains

Review of manufacturer’s specifications and limitations for

rigging equipment

Lesson 9: Inspection of Ropes & Rigging Equipment

- Inspection process and safety checklists, including what to

inspect, how to inspect, how frequently to inspect - Identification of wear, defects, and failure signs in all rigging

equipment - Steps to take if a hazard is discovered.

- Maintenance, repair/replacement of rigging equipment, rope,

rigging equipment, etc.

Lesson 10: Crane and Hoisting Machine Overview

Overview of common types of cranes, hoisting machines and hazards associated with, including:

- Crush hazards

- Struck by objects

- Fall hazards

- Electrical hazards

Overview of crane and hoisting machine setup, including:

- Ground Conditions

- Tiebacks for mini cranes

- Outrigger cribbing and placement

Lesson 11: Communication between workers & supervisoes while rigging

- Radios

- Hand signals

- Flags, etc.

Lesson 12: General Principles of Fall Protection

- Fall CLearance

- Total Fall Distance Calculations

- Minimizing Fall Forces

- Guarding Against Falling Objects

Lesson 13: Personal Protective Equipment and Fall Arrest Systems

- Inspection Procedures

- Donning, Doffing Harness, and Equipment

- Care of Equipment and Systems

Lesson 14: General Construction Site Hazards

Pricing

Group

Minimum 5 person per class-

We Come to You

-

Schedule Flexibility

-

Hands-on Training

Inquire about setting up a private class for your team and ask about group discounts.

To successfully complete the training, students must:

- Earn a minimum score of 75% on the final evaluation.

- Complete 100% of the required course content.

- Completion of required pre-and post-quiz assessment

- Actively participate in all written and practical learning activities.

- Completion of Continuing Education and Training Registration Form

Please note that no make-up time will be provided for missed assignments or activities.

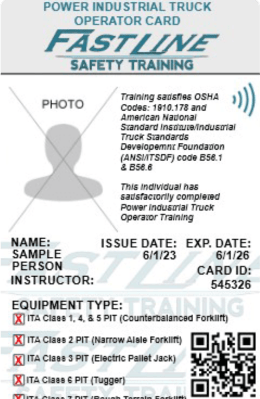

The Preferred Equipment Operator Card

QR Code/ NFC Technology

Digital ID Card: Quickly scan your card with any smartphone camera to experience the convenience of your digital identification profile.

Blockchain Protected

Blockchain-protected: Experience the next generation of security. Leveraging the power of blockchain technology, your cards are encrypted and tamper-proof, ensuring your information is always safe.

ID Cards with Face Photo

Full-resolution ID Cards: Fast Line Safety Training issues A standard identification card featuring a full-color photograph of the individual.

Completion cards are valid for 3 years and in all 50 states.

We are the only providers issuing such permanent cards.

Book your next training course with us.

Fill out the form below or call us at (631) 393 – 6755

to set up your training session!

l out the form below or

call us at (631) 393 – 6755

to set up your training session!

Frequently Asked Questions

What is the purpose of a 16-hour Rigging Worker Refresher Coruse?

- Maintain Compliance: to ensure you’re working within the latest

- Enhance Safety: Review and update your knowledge of safe rigging practices, minimizing the risk of accidents and injuries

- Refine your skills in areas such as load balancing, knot tying, equipment inspection, and hazard recognition

- Boost Confidence: Gain renewed confidence in your ability to perform rigging tasks safely and efficiently

Who should take a 16-hour rigging worker refresher course?

- Individuals whose current 16-Hour Rigging Worker certification has expired

- Riggers who work in industries where regular safety training is required

- Anyone who feels their rigging knowledge or skills could be improved

What are the benefits of taking a Refresher Course?

- Reduced Risk of Accidents

- Increased Job Security

- Enhanced Efficiently

- Improved Communication

How can I maintain my rigging skills between refresher course?

- Stay informed: Keep up-to-date on industry best practices and safety regulations through industry publications, online resources, and attending safety seminars

- Practical Safe Habits: Continuously apply safe rigging techniques in your daily work and encourage safe work practices among your colleagues

- Regular Inspection: Conduct regular inspections of your rigging equipment to identify and address any potential issues