Cranes are indispensable giants on construction sites, capable of lifting and moving incredible loads that are important to building our infrastructure and skylines; however, significant responsibility comes with the power that comes with it. Crane operations are complex and pose serious risks if not managed with careful attention to safety. This “Crane Safety 101” guide highlights the fundamental principles and practices for keeping everyone on the job site safe around these powerful machines. Ignoring crane safety protocols can lead to catastrophic accidents, including dropped loads, tip-overs, collapses, and contact with power lines, resulting in severe injuries or fatalities. A strong safety culture and a thorough understanding of best practices are the bedrock of preventing such incidents.

Here are the critical components of crane safety that every construction professional should be aware of:

The Right Crane for the Job

Safety begins before the first lift. Selecting the appropriate type of crane for the specific task and site conditions. Factors such as load weight, reach required, site accessibility, and ground conditions all influence the choice between mobile cranes, tower cranes, and other specialized lifting equipment. Using a crane that is not suited for the job significantly increases the risk of failure.

Qualified and Trained Personnel

Only properly trained and certified operators, riggers, and signal persons should be involved in crane operations. Each role requires specific knowledge and skills to ensure that the crane is operated correctly, loads are appropriately secured, and communication is clear and understandable. Regular training and safety courses are vital to keep skills sharp and knowledge up-to-date with the latest safety standards and technologies.

Thorough Planning and Risk Assessment

Take the time to plan every lift carefully, including assessing the weight and nature of the load, determining the correct rigging, planning the lift path to avoid obstacles (especially power lines), and ensuring the landing zone is clear and prepared. A detailed lift plan should be communicated to all involved personnel, particularly for critical lifts. Identifying potential hazards and implementing control measures before the lift begins is paramount.

Pre-Operation Inspections Checklist

A qualified person’s daily crane inspection before operation begins is non-negotiable. This inspection should cover all critical components, including ropes, hooks, slings, brakes, controls, and safety devices. Any personnel must report system errors before the crane is put into service. Regular preventative maintenance is also essential to ensure the crane remains in good working order. Remember the user’s emphasis on keeping tools in tip-top shape, which applies to cranes.

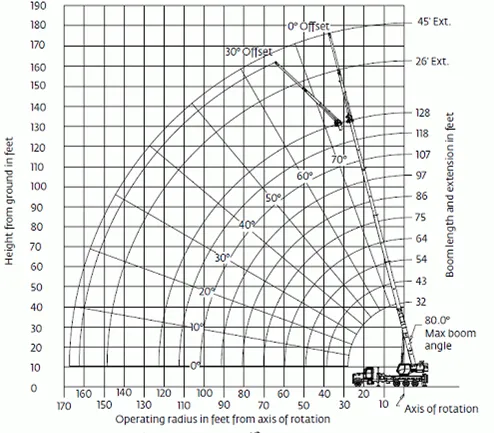

Understanding Crane Load Limits and Load Charts

The crane operator must never exceed the crane’s load capacity. Operators must fully understand the crane’s load chart, which details the maximum weight that can be lifted at various angles and boom configurations. Overloading is a leading cause of crane failures and must be avoided at all costs. Rigging also plays a critical role in load management, ensuring the load is balanced and secured correctly.

Ground Conditions and Proper Equipment Setup

The ground beneath a crane must be firm, level, and capable of supporting the crane’s weight and the load. Uneven or unstable ground surfaces can lead to the crane tipping over. For mobile cranes, proper deployment and setup of outriggers or stabilizers, using adequate mats or cribbing, is essential for creating a stable support base.

Clear Communication

Communicating between the crane operator, riggers, and signal person is vital during lifting operations. Workers should use a combination of hand signals and radios during active construction sites. Anybody near heavy equipment must be able to clearly understand hand signals and communicate effectively in many different scenarios.

Environmental Factors

Weather conditions can significantly impact crane operations. Wind, rain, lightning, and extreme temperatures can all pose risks. Operators must know the crane’s wind speed limits and be prepared to cease operations when weather conditions become hazardous. Visibility is also crucial for safe operation.

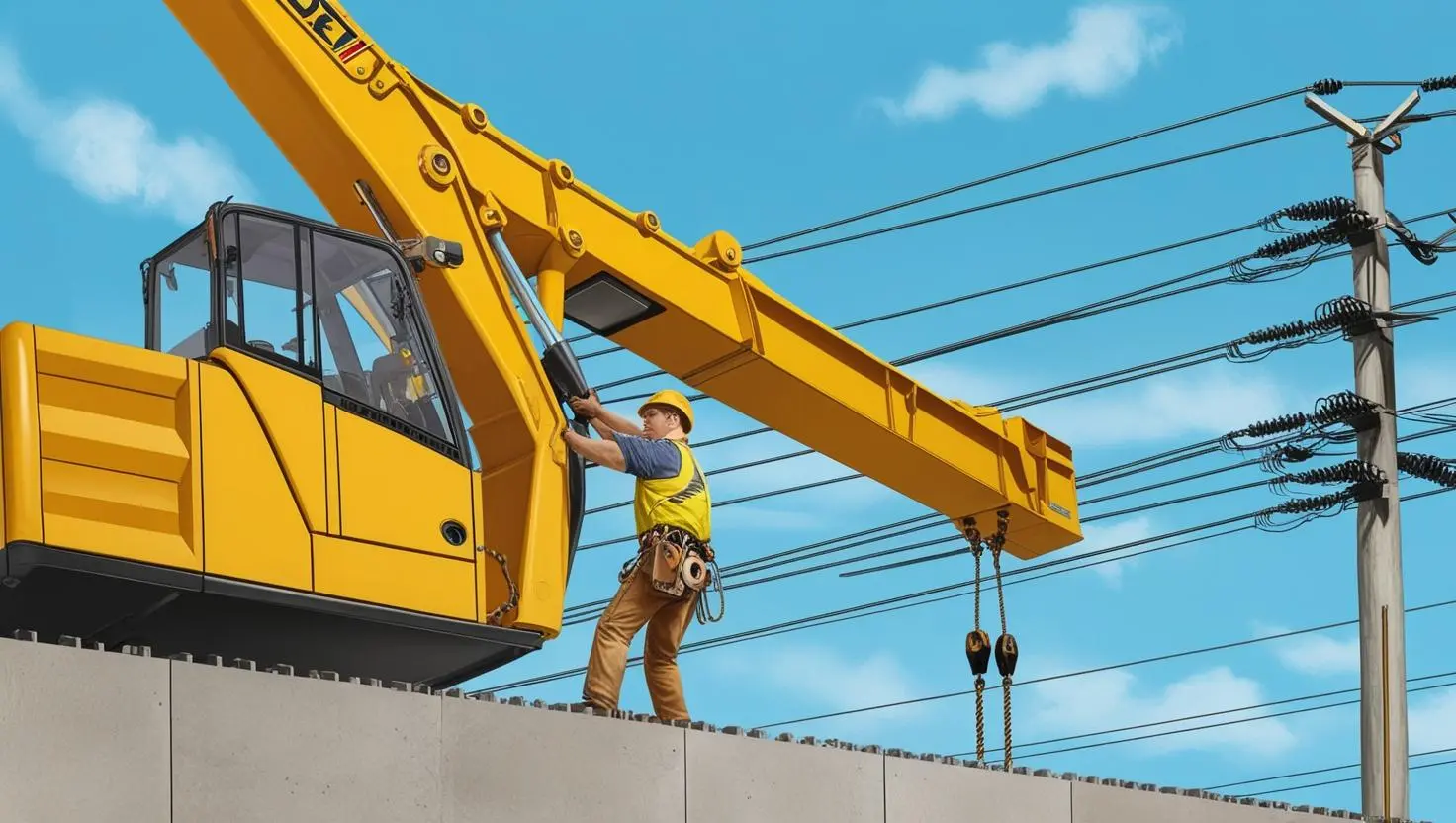

Avoiding Obstacles During Operation

Contact with overhead power lines is one of the most dangerous hazards associated with crane operations and is a leading cause of fatalities. The crane must maintain a safe distance from power lines. During their lift planning, a thorough site survey should identify the location of all power lines and any other surrounding structures.

Emergency Procedures

All personnel on site should be aware of the emergency procedures in place during a crane incident. Workers should know how to react to a power line contact, a dropped load, or a crane malfunction.

Crane safety is a shared responsibility. By adhering to these fundamental principles, maintaining equipment, ensuring proper training, and fostering a strong safety culture, we can significantly reduce the risks associated with crane operations and ensure that everyone goes home safely at the end of the day. Lifting standards for safety are just as important as lifting materials on the construction site.

Frequently asked Questions

Q: How is the maximum load capacity of a crane determined?

A: The maximum load capacity of a crane determined by the manufacturer and is detailed in the crane’s load chart.. This chart considers factors such as the crane’s configuration, boom length/angle and operating radius. It is crucial to consult the load chart before every lift and never exceed the stated capacity.

Q: How often should a crane be inspected?

A: Cranes require regular inspections. A visual inspection should be conducted by the operator before each shift. More detailed inspections by a competent person are required at regular intervals (daily, monthly, annually) as specified by regulations and manufacturer recommendations.

Q: What should I do if i see an unsafe condition related to a crane?

A: IF you observe any unsafe condition involving a crane, such as a damaged sling, a crane being too close to dangerous structures, or an operator who appears fatigued. You should immediately report it to your supervisor or the designated safety officer on site.

Q: What are the potential consequences of overloading a crane?

A: Overloading a crane can have sever consequences, including structural damage to the crane, boom failure, tipping, and the dropping of the load. This can result in significant property damage, serious injuries, or fatalities.

Q: What is rigging, and why is it important for crane safety?

A: Rigging involves the equipment and techniques used to attach a load to the crane hook safely. Proper rigging ensures the load is secure, balanced, and will not shift or fall during the lift. Using the correct slings, shackles, and other rigging gear, and inspecting them before use, are vital safety practices.