Safety is paramount when operating heavy machinery, especially when it comes to scissor lifts. These versatile machines are a staple in many construction sites, but like all equipment, they require regular checks to ensure they’re in optimal working condition. This is where the importance of a scissor lift daily inspection checklist comes into play.

Before diving into the specifics of the checklist, it’s crucial to understand why these inspections are necessary. Regular inspections can identify potential issues before they become significant problems, ensuring the safety of the operator and those around the equipment. Moreover, adhering to scissor lift inspection requirements can also prolong the lifespan of the equipment, saving costs in the long run.

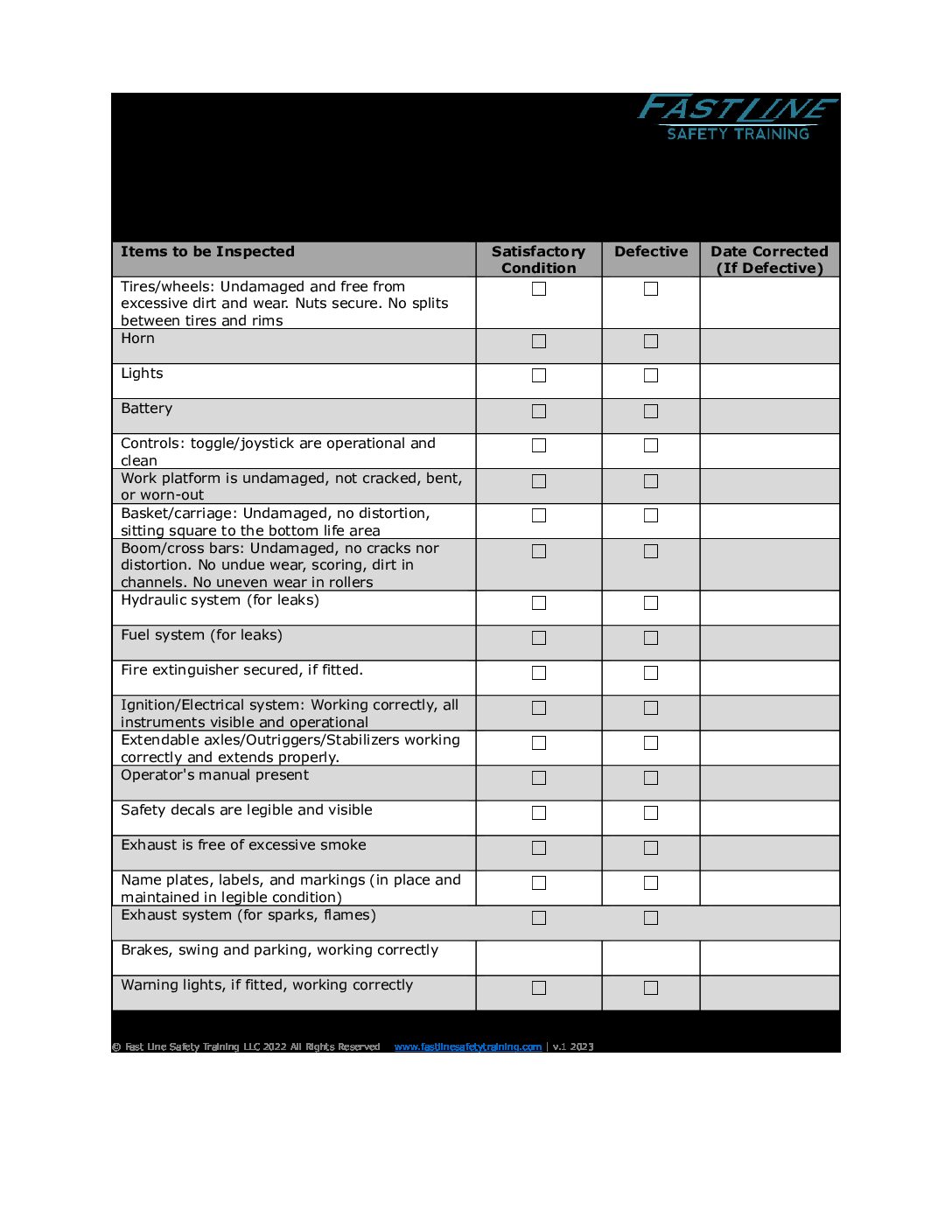

Scissor Lift Inspection Form: Key Components

Fast Line Safety Training’s comprehensive scissor lift inspection form covers all the essential areas that need checking before operating the equipment. Here are some of the critical components to inspect:

Tires/Wheels: Ensure they are undamaged, free from excessive dirt and wear. Check for secure nuts and no splits between tires and rims.

Controls: Toggle/joystick should be operational and clean.

Work Platform: It should be undamaged, not cracked, bent, or worn out.

Basket/Carriage: Ensure it’s undamaged, with no distortion and sits square to the bottom lift area.

Boom/Cross Bars: Check for damages, cracks, or distortions. Ensure there’s no undue wear, scoring, or dirt in channels.

Hydraulic and Fuel Systems: Look out for any leaks.

Ignition/Electrical System: Ensure it’s working correctly with all instruments visible and operational.

Safety Decals: They should be legible and visible.

Exhaust System: Check for sparks, flames, and ensure it’s free of excessive smoke.

Brakes and Warning Lights: Ensure they’re working correctly.

The Risks of Neglecting Scissor Lift Inspections

Neglecting the routine inspection of your scissor lift can lead to a myriad of problems, some of which can be catastrophic. Here are some of the risks and potential consequences:

Accidents and Injuries: Without regular checks, malfunctioning parts can lead to accidents, potentially causing severe injuries or even fatalities.

Equipment Damage: Overlooking minor issues can escalate into significant damages, leading to costly repairs or replacements.

Operational Delays: A malfunctioning scissor lift can halt operations, leading to project delays and increased costs.

Legal Repercussions: Failing to adhere to safety standards can result in hefty fines and legal actions against the responsible parties.

Reputation Damage: Accidents and negligence can tarnish the reputation of a company, making it challenging to secure future projects or clients.

Why Choose Fast Line Safety Training?

Fast Line Safety Training is one of the leading Scissor Lift and Boom Lift certification providers in NY. With a commitment to safety and excellence, our training programs are designed to equip operators with the knowledge and skills they need to operate machinery safely and efficiently.

If you’re in the construction industry and require Scissor Lift or Boom Lift Certifications, don’t hesitate to reach out. With our expertise and dedication to safety, you’re in good hands.

Remember, regular inspections using a scissor lift inspection form are not just a requirement – they’re a responsibility. Ensure the safety of everyone on your site by making these inspections a daily routine.

To access a downloadable PDF version of the Pre-use Scissor Lift Inspection form by Fast Line Safety Training, click here.

For more information about our comprehensive Scissor Lift and Boom Lift Training Course, click here.