In today’s fast-paced world, keeping workplaces safe is key. Hazardous materials can be very dangerous to workers. That’s why HAZWOPER training is so important.

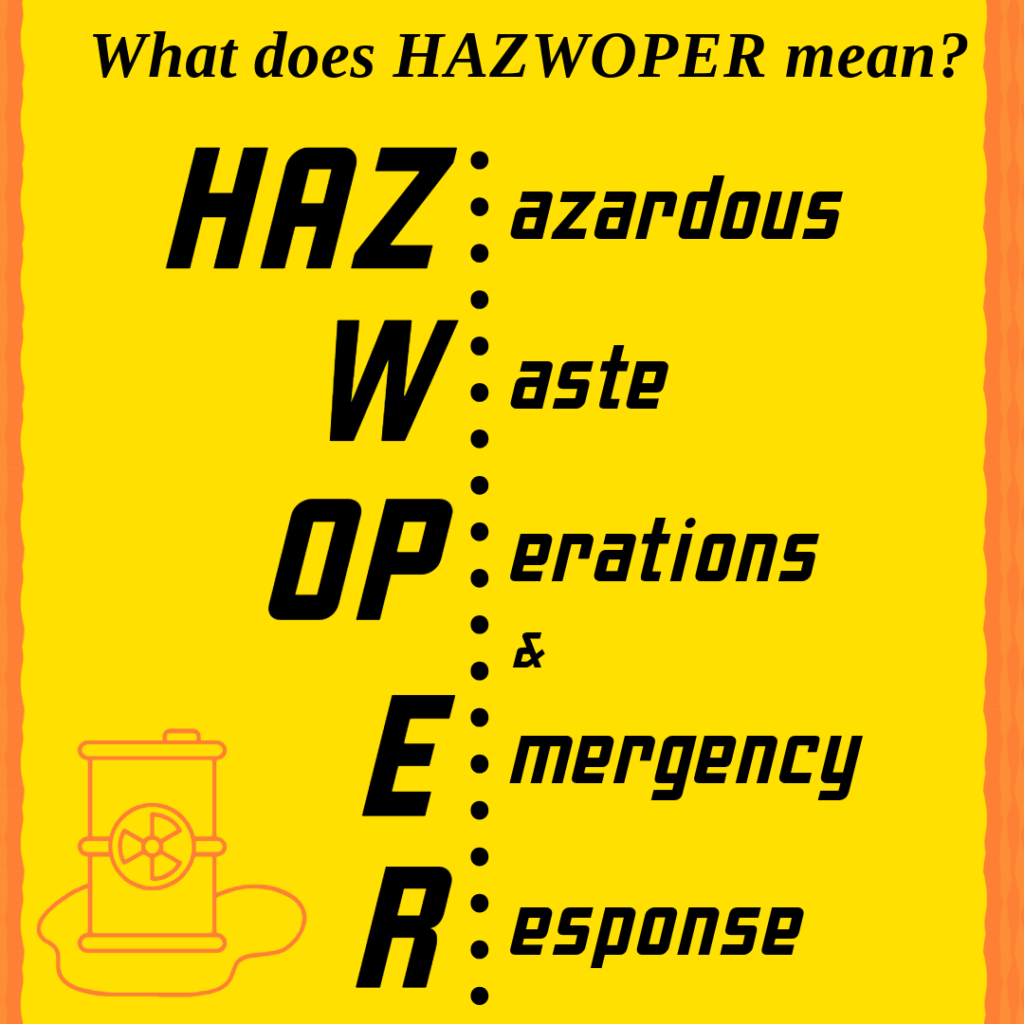

HAZWOPER stands for Hazardous Waste Operations and Emergency Response. It teaches workers how to safely handle hazardous materials. It also shows them how to act in emergencies.

Key Takeaways

- HAZWOPER certification is essential for ensuring workplace safety in industries handling hazardous materials

- Proper employee training is crucial to prevent accidents and minimize potential harm to workers and the environment

- Compliance with OSHA standards is a legal requirement for companies dealing with hazardous waste

- Investing in HAZWOPER training protects workers, mitigates risks, and safeguards a company’s reputation

- Employers have a responsibility to prioritize workplace safety and provide adequate HAZWOPER training to their workforce

Understanding HAZWOPER and Its Significance

In industries that handle hazardous waste, keeping workers safe is key. HAZWOPER is a vital framework for protecting employees from harmful substances. It ensures their safety in emergency situations.

What is HAZWOPER?

HAZWOPER means Hazardous Waste Operations and Emergency Response. It’s a set of rules from the Occupational Safety and Health Administration (OSHA). These rules help keep workers safe in hazardous waste cleanup and emergency responses.

These regulations apply to many industries. This includes construction, manufacturing, and environmental services.

Why is HAZWOPER important for workplace safety?

HAZWOPER training teaches workers how to handle hazardous situations. They learn about safety procedures, personal protective equipment (PPE), and emergency plans. This training is essential for their safety.

"Safety is not a goal to be reached, but a way of life" -Anonymous

By invensting in HAZWOPER training, companies follow OSHA rules. This creates a safer work environment. Well-trained workers are less likely to get hurt or sick from hazardous substances.

This leads to better health, less lost time, and higher productivity. It’s a win-win for everyone.

Identifying Hazardous Waste and Emergency Response Situations

It’s key to know hazardous waste and emergency situations to keep workplaces safe and protect the environment. Hazardous materials have different properties and risks. Some common types include:

- Flammable liquids and solids

- Corrosive substances

- Toxic chemicals

- Reactive materials

- Explosive or shock-sensitive items

First, you need to identify hazardous materials properly. This step helps manage these substances and lowers the risk of chemical exposure and environmental contamination. To do this, you should:

Steps for identifying Hazardous materials

- Check Safety Data Sheets (SDS) for each material

- Learn about the hazard communication system, like labels and pictograms

- Regularly inspect and audit storage areas and containers

Next, risk assessment is crucial for managing hazardous waste. It involves looking at the dangers of each material and how likely and severe the effects could be. Risk assessment helps focus on safety and guides emergency response planning.

"By failing to prepare, you are preparing to fail"

Having a good emergency response plan is vital for handling hazardous waste incidents. A solid plan should include:

| Component | Description |

| Evacuation Procedures | Clear instructions for safely evacuating the area in case of an emergency |

| Containment Strategies | Methods for isolating and controlling the spread of hazardous materials |

| Common Protocols | Established channels for communicating with emergency responders and relevant authorities |

| Training and drills | Regular training and practice exercises to ensure readiness and competence |

By focusing on identifying hazardous materials, assesing risks, and planning for emergencies, organizations can greatly reduce accidents, injuries and environmental harm from hazardous waste.

OSHA Standards and Requirements for HAZWOPER Certification

OSHA sets rules to keep workers safe in hazardous waste jobs and emergencies. These rules cover training, gear, and steps employers must take. This helps reduce risks when handling dangerous materials.

OSHA 29 CFR 1910.120 Standarrd

The main osha rule for HAZWOPER is 29 CFR 1910.120. It applies to several work places:

- Cleanup operations at uncontrolled hazardous waste sites

- Corrective actions involving clean-up operations at a site covered by the Resources Conservation and Recovery Act (RCRA)

- Voluntary clean-up operations at uncontrolled hazardous waste sites

- Operations involving hazardous wastes conducted at treatment, storage, and disposal facilities

- Emergency response operations for releases of hazardous substances

This Standard sets training needs for workers based on their roles and exposures to hazards.

To learn more specifics go to the Official OSHA Regulation for 1910.120

Employer Responsibilities in Ensuring HAZWOPER Compliance

Employers are key in keeping workers safe from hazardous waste. They must:

- Give the right HAZWOPER training to employees

- Do a detailed hazard check of the work area

- Make and follow a safety and health plan

- Give workers the right personal protective equipment (PPE)

- Set up decontamination and emergency plans

Employers also need to keep records of training, health checks, and exposure monitoring. Not following these rules can lead to big fines and legal trouble.

| Employers Responsibility | OSHA Requirements |

| Worker Tranining | Provide Appropiate HAZWOPER training based on job duties and exposure levels |

| Hazard Assesment | Conduct a thorough hazard assesment of the worksite |

| Safety and Health Program | Develop and implement a written safety and health program |

| Personal Protective Equipment | Supply workers with necessary PPE |

| Decotamination and Emergency Response | Establish decontamination procedures and emergency response plans |

"Employers who prioritize HAZWOPER compliance not only protect their workers but also demonstrate a commitment to responsible business practices and environmental stewardship."

By following OSHA rules and focusing on worker training and safety procedures, employers can make a safer workplace. This reduces risks in hazardous waste jobs and emergency situations.

Different Levels of HAZWOPER Training

Employees must get the proper HAZWOPER training. This depends on their job and how they might be exposed to dangerous substances. OSHA has set up different training levels for various worker roles.

Fast Line Safety Training is here to help bring our expertise by going into detail to keep yourself safe at work.

40 Hour Hazwoper Training

The 40-hour course is for those who work directly with hazardous waste sites or emergency responses. It mixes classroom learning with hands-on training. Topics include site safety, risk assessment, and how to clean up safely.

After finishing, workers get certified. This shows they’re ready to handle dangerous situations safely.

Link to get your workforce trained:

24 Hour Hazwoper Training

The 24-hour course is for those with occasional exposure to hazardous substances. It’s for workers who don’t clean up but might handle hazardous materials. The course teaches safety basics, hazard recognition, and how to respond.

It also includes training on using protective gear and emergency actions.

8 Hour HAZWOPER Refresher Training

Workers need an 8-hour refresher course every year to keep their certification. This course updates their knowledge and skills. It also covers new regulations and best practices.

Employers must keep track of who needs this training. They must make sure workers get the refresher courses to follow OSHA rules.

Need a refresher? No Problem:

What is HAZWOPER certification?

HAZWOPER stands for Hazardous Waste Operations and Emergency Response. It’s a training needed by OSHA for workers in hazardous waste and emergency response. This training makes sure employees can handle hazardous materials safely and respond well in emergencies.

Who needs HAZWOPER certification?

Workers in clean-up, emergency response, and handling hazardous substances need HAZWOPER. This includes people in construction, environmental services, and chemical manufacturing.

What are the different levels of HAZWOPER training?

There are three levels of HAZWOPER training. The 40-hour training is for those directly involved. The 24-hour training is for occasional workers and supervisors. The 8-hour refresher is needed every year to keep certification.

What topics are covered in HAZWOPER traning?

HAZWOPER training includes many topics. These are identifying hazardous materials, risk assessment, and personal protective equipment. It also covers decontamination, emergency plans, and incident command systems. The training includes hands-on exercises for practical experience.

How often do workers need to renew their HAZWOPER certification?

Workers must renew their HAZWOPER certification every year. This is done through an 8-hour refresher course. It keeps workers updated on safety regulations and best practices.

What are the benefits of HAZWOPER certification for employers?

Employers benefit from HAZWOPER certification. It shows they care about safety, reduces accidents, and follows OSHA rules. This can lower costs, improve morale, and enhance reputation.