Course Duration

40 Hours

Course Session

5 Session

Language

English, Spanish

Training Type

Classroom Training

Course Overview

40-Hour HAZWOPER training is a mandatory requirement for laborers, general site workers, and other personnel who may be exposed to hazardous substances during their job duties. This comprehensive training program, mandated by OSHA standard 29 CFR 1910.120, ensures that workers are equipped with the knowledge and skills necessary to safely perform tasks in hazardous waste operations and emergency response scenarios.

By completing this course, participants will gain the knowledge and skills necessary to work safely with hazardous materials, minimizing the risk of injury or illness and ensuring compliance with all regulatory requirements

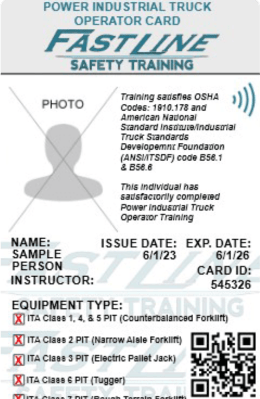

Fast Line Safety Training delivers high-quality, hands-on training at your location and provides the industry’s preferred operator card.

Additional Course Information

What you'll learn

- Recognize and evaluate hazardous materials

- Understand the principles of hazard communication

- Implement Safe work practices

- Develop emergency response plans

- Understand OSHA regulations

- Perform site surveys and hazard assessments

- Develop and implement safe work procedures

CEU Credits Earned

4.0

Continuous Education Units

Who should take this 40-Hour HAZWOPER Course?

This 40-Hour HAZWOPER course is mandatory for any employee who may be exposed to hazardous substances during their job duties, including:

- Construction Heavy Equipment Operators

- Waste management workers

- Industrial workers

- Construction workers

- Environmental professionals

- Anyone involved in the handling, storage, or disposal of hazardous materials

Learning Outcomes

OSHA standards state that HAZWOPER training applies to workers and employers involved in five specific types of operations:

- Uncontrolled hazardous waste cleanup operations required by a government body

- Corrective actions involving cleanup operations at Resource Conservation and Recovery Act (RCRA) sites

- Hazardous waste operations at treatment, storage and disposal (TSD) facilities

- Operations at non-TSD facilities that generate hazardous waste

- Emergency response actions involving the potential release of dangerous substances

See OSHA’s HAZWOPER standards for additional information

How Long is This Certification valid for?

The 40-hour HAZWOPER certification is valid for:

12 Months

To maintain your certification, you must complete an additional 8-hour HAZWOPER Refresher course each year. If you miss the deadline, you may be required to retake the 40-hour course. See HAZWOPER 8-HOUR REFRESHER COURSE for additional information.

Course Outline

Lesson 1: Introduction to Hazardous Waste Operations and Emergency Response

- Overview of HAZWOPER regulations(29 CFR 1910.120)

- Legal and regulatory requirements

- Role of employees and employers in hazardous waste operations

- Introduction to risk assessment and hazard control

Lesson 2: Types of Hazards

Physical Hazards:

- Noise

- Vibration

- Temperature extremes (heat stress, cold stress)

- Radiation

- Ergonomics

Chemical Hazards:

- Corrosives

- Flammables

- Explosives

- Toxics

- Carcinogens

- Reactives

- Oxidizers

- Water-reactive materials

Biological Hazards:

- Bloodborne pathogens

- Respiratory hazards (mold, bacteria)

Physical Hazards:

- Fall hazards

- Slip, trip, and fall hazards

- Struck-by hazards

- Caught-in hazards

Lesson 3: Personal Protective Equipement (PPE)

Selection criteria for PPE

Types of PPE:

- Eye and face protection (safety glasses, goggles, face shields)

- Respiratory protection (air-purifying respirators, supplied-air respirators, SCBA)

- Chemical protective clothing (liquid splash suits, vapor protective suits)

- Hand protection (gloves)

- Foot protection (safety shoes, boots)

- Fall protection (harnesses, lifelines)

- Protective clothing (coveralls, aprons)

- Decontamination equipment

Lesson 4: Levels of Protection

- Understanding hazard severity and risk assessment

- Implementing appropriate control measures (engineering, administrative, PPE)

- Hierarchy of controls

- Selecting the appropriate level of protection based on hazard assessment

Lesson 5: Decontamination

- Principles of decontamination

- Procedures for different types of contaminants (chemical, biological)

- Decontamination equipment and techniques

- Personal decontamination

- Emergency decontamination

Lesson 6: Toxicology

- Basic principles of toxicology

- Routes of exposure

- Dose-response relationships

- Acute and chronic toxicity

- Effects of exposure on human health

- Medical monitoring and surveillance

Lesson 7: Fire Prevention and Response

- Fire safety principles (fire triangle)

- Fire prevention measures

- Housekeeping

- Electrical safety

- Hot work permits

- Flammable liquids storage

- Fire suppression systems

- Fire extinguisher training

- Fighting fires involving hazardous materials (limited to defensive actions)

Lesson 8: Hazardous Materials

- Hazard Communication Standard (GHS)

- Safety Data Sheets (SDS)

- Labeling and marking of hazardous materials

- Emergency Response Guidebook (ERG)

- Placarding and shipping regulations

Lesson 9: Medical Surveillance

- Importance of medical surveillance programs

- Types of medical examinations

- Employee health records

- Immunizations

Lesson 10: Site Emergencies

- Emergency response planning

- Evacuation procedures

- First aid and CPR

- Incident command system (ICS)

- Spill control and cleanup

- Emergency response to hazardous materials releases

Lesson 11: Drums and Containers

- Safe handling and storage of materials in drums and containers

- Lifting techniques

- Spill control and cleanup

Lesson 12: Fall Hazards

- Recognizing and evaluating fall hazards

- Fall protection systems (guardrails, safety nets, personal fall arrest systems)

- Fall restraint systems

Lesson 13: Electrocution

- Electrical safety principles

- Lockout/tagout procedures

- Electrical hazards in the workplace

Lesson 14: Struck-By Hazards

- Identifying and controlling struck-by hazards

- Safe work practices around moving equipment

- Personal protective equipment for struck-by hazards

Lesson 15: Caught-in Hazards

- Recognizing and preventing caught-in hazards

- Safe work practices in confined spaces

- Machine guarding

Lesson 16: Hazardous Communication

- Hazard Communication Standard (GHS)

- Safety Data Sheets (SDS)

- Labeling and marking of hazardous materials

- Employee training and awareness

Pricing

Group

Minimum 5 person per class-

We Come to You

-

Schedule Flexibility

-

Hands-on Training

Inquire about setting up a private class for your team and ask about group discounts.

To successfully complete the training, students must:

- Earn a minimum score of 75% on the final evaluation.

- Complete 100% of the required course content.

- Completion of required pre-and post-quiz assessment

- Actively participate in all written and practical learning activities.

- Completion of Continuing Education and Training Registration Form

Please note that no make-up time will be provided for missed assignments or activities.

The Preferred Equipment Operator Card

QR Code/ NFC Technology

Digital ID Card: Quickly scan your card with any smartphone camera to experience the convenience of your digital identification profile.

Blockchain Protected

Blockchain-protected: Experience the next generation of security. Leveraging the power of blockchain technology, your cards are encrypted and tamper-proof, ensuring your information is always safe.

ID Cards with Face Photo

Full-resolution ID Cards: Fast Line Safety Training issues A standard identification card featuring a full-color photograph of the individual.

Completion cards are valid for 3 years and in all 50 states.

We are the only providers issuing such permanent cards.

Book your next training course with us.

Fill out the form below or call us at (631) 393 – 6755

to set up your training session!

l out the form below or

call us at (631) 393 – 6755

to set up your training session!

Frequently Asked Questions

What is HAZWOPER and why is this training important?

HAZWOPER stands for Hazardous Waste Operations and Emergency Response. This comprehensive training is crucial for workers who may be exposed to hazardous substances during their job duties

Who regulates HAZWOPER training?

HAZWOPER training is regulated by the Occupational Safety and Health Administration(OSHA) under 29 CFR 1910.120

What are the potential health risks associated with working with hazardous materials?

Potential health risks can include illnesses, and Exposure to hazardous materials can also pose significant safety risks, including fires, explosions, and chemical burns

How often is HAZWOPER refresher training required

Workers who complete the 40-hour HAZWOPER training are typically required to complete an 8-hour refresher course annually to maintain their certification