PA Electric Pallet Jack Training & Certification

Course Duration

4 Hours

Course Session

1 Session

Language

English, Spanish

Training Type

Classroom Training

Course Overview

Our Electric Pallet Jack training course curriculum combines a plethora of training, such as formal instruction, practical training and learning, and assessing the operators performance in the workplace and with equipment.

This only covers Electric Pallet Jack, however, Fast Line Safety Training also offers a complete Powered Industrial Truck Course that combines the below trainings into one course:

Fast Line Safety Training delivers high-quality, hands-on training at your location and provides the industry’s preferred operator card.

Powered Industrial Truck (P.I.T.) Operator Training

- Counterbalance ForkliftClass 1, 4, & 5

- Stand-up Narrow Aisle ForkliftClass 2

- Electric Pallet JackClass 3

- Rough Terrain ForkliftClass 7

Additional Course Information

What you'll learn

- Safe operating procedures

- Battery Safety and Maintenance

- Load stability and weight limits

- Pre-operational inspections

- Emergency procedures

- Ramp Safety

- Load securing methods

- Maneuvering in confined spaces

This Training is valid for:

3 Years

Retraining is essential to ensure that operator’s skills remain updated, and they continue to operate forklifts safely and efficiently.

Who Should Attend this Electrical Pallet Jack Training Course?

This course is designed for anyone who operates or works around electric pallet jacks, including:

- Warehouse workers

- Forklift operators

- Material handlers

- Supervisors

- And anyone responsible for ensuring safe and efficient material handling operations.

Whether you are new to operating electric pallet jacks or seeking to refresh your skills and enhance your safety knowledge, the training will provide you with the essential skills and knowledgej to operate these machines safely and effectively.

Learning Outcomes

Upon completion of the Pallet Jack Training and Certification course, participants will be proficient in:

- Identifying and explaining various types of powered industrial trucks and their applications.

- Articulating safety procedures and preventative measures to mitigate powered industrial truck hazards.

- Demonstrating the safe maneuvering of manual and electric pallet jacks.

- Conducting pre-operation inspections, recognizing operational defects, and completing the necessary checklists.

Advanced Pallet Jack Certification with Fast Line Safety Training

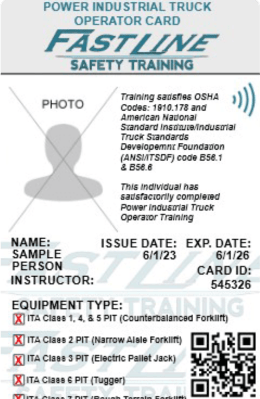

At Fast Line Safety Training, we’re dedicated to offering more than just exceptional training. Upon course completion, students immediately receive on-site temporary cards. However, our standout feature is the permanent ID cards embedded with NFC technology.

These NFC-enabled ID cards, valid for three years and recognized across all 50 states, simplify the verification process. A quick tap or proximity of a smartphone to the card’s NFC chip provides instant training verification, bypassing traditional paperwork.

By choosing Fast Line Safety Training, you’re ensuring unparalleled training without any logistical complications. Step into the future of safety training with us.

Live on one of these states? We Travel To You!

Fast Line Safety Training is proud to offer this certification across New York, New Jersey and Pennsylvania. Explore the links below to discover more about this certification in other areas:

Course Outline

This Course outline provides a general overview of the topics to be covered. The actual course content may be adjusted slightly based on the specific needs and learning styles of the participants

Lesson 1: Introduction

- Welcome and Introductions

- Course Objectives and Overview

- Importance of Electric Pallet Jack Training

- Safety Culture and Accident Prevention

- Risk Factors and Statistics

Lesson 2: Understanding Electrical Pallet Jacks

- What is a Powered Industrial Truck (PIT)?

- Types of Electric Pallet Jacks:

- Class 1 Electric Truck

- Class 2 Electric Truck

- Class 3 Electric Truck

- Components of an Electric Pallet Jack:

- Mast, Forks, Wheels, Controls, Battery

- Data Plate Information

- Load Capacity and Weight Limits

Lesson 3: Safe Operating Procedures

- Federal, State, and Company Regulations

- Operator Daily Checklist

- Pre-Operational Inspections

- Safe Travel Rules

- Steering Modes

- Intersection Procedures

- Emergency Stops / Braking

- Safe Load Handling Concepts

- Center of Gravity

- Combined Center of Gravity

- Centrifugal Force

- Inertia

- Load Center

- Picking up a Load

- Traveling with a Load

- Placing a Load

- Ramp Procedures

- Dock Procedures

- Safe Battery Handling

- Safe Battery Charging Area

- Don’t Leave Your PIT Unattended

- Safe Parking Rules

Lesson 4: Hazard Recognition and Control

- Facility Characteristics

- Safety Decals

- Safety Devices

- Forks

- Tires

- What Do They Weigh?

- First Rules of Safety

Lesson 5: Practical Application

- Hands-on Demonstrating or Simulation

- Practice Maneuvering and Load Handling

- Question and Answering Session

Lesson 6: Conclusion

- Summary and Key Takeaways

- Certification/Evaluation

- Resources and Additional Information

- Feedback and Evaluation

Pricing

Group

Minimum 5 person per class-

We Come to You

-

Schedule Flexibility

-

Hands-on Training

Inquire about setting up a private class for your team and ask about group discounts.

To successfully complete the training, students must:

- Earn a minimum score of 75% on the final evaluation.

- Complete 100% of the required course content.

- Completion of required pre-and post-quiz assessment

- Actively participate in all written and practical learning activities.

- Completion of Continuing Education and Training Registration Form

Please note that no make-up time will be provided for missed assignments or activities.

The Preferred Equipment Operator Card

Students that satisfactorily complete the course are issued a temporary card onsite.

Completion cards are valid for 3 years and in all 50 states

QR Code/ NFC Technology

Digital ID Card: Quickly scan your card with any smartphone camera to experience the convenience of your digital identification profile.

Blockchain Protected

Blockchain-protected: Experience the next generation of security. Leveraging the power of blockchain technology, your cards are encrypted and tamper-proof, ensuring your information is always safe.

ID Cards with Face Photo

Full-resolution ID Cards: Fast Line Safety Training issues A standard identification card featuring a full-color photograph of the individual.

Completion cards are valid for 3 years and in all 50 states.

We are the only providers issuing such permanent cards.

Book your next training course with us.

Fill out the form below or call us at (484) 205 – 9802

to set up your training session!

l out the form below or

call us at (631) 393 – 6755

to set up your training session!

Frequently Asked Questions

Who Needs Pallet Jack Certification Training?

Our Pallet Jack Training and Certification course is meticulously designed for new warehouse workers and other employees who operate electric or manual pallet jacks, also known as pallet trucks, pump trucks, and hand trucks.

Age Requirement: Operators must be at least 18 years old to be certified for motorized pallet jack operation.

OSHA Compliance: In alignment with OSHA standards, our course mandates formal instruction, practical training, and a performance evaluation for motorized pallet jack operators.

How Long will My Pallet Jack Certification Last?

Here at Fast Line Safety Training Certifications from our courses are valid for three years from the day they are issued.

Is it required to do Retraining Courses?

Retraining is essential and mandatory under specific circumstances, such as unsafe operation observations, accidents, near-miss incidents, or the introduction of new pallet jack types or altered workplace conditions affecting safe operations.

What are the safety risks associated with operating an electric pallet jack?

Operating electric pallet jacks carries inherent risks, including collisions with pedestrians or other vehicles, tipping over, crushing injuries, and electrical hazards. Improper operation can also lead to damage to the equipment or the goods being transported.

What are the common causes of electric pallet jack accidents, and how can they be prevented?

Common causes include:

- Speeding: Operating the jack too quickly can lead to loss of control

- Improper loading: overloading the jack or improperly loading the pallet can cause instability and tipping

- Distractions: Such as talking on a phone or texting can impair operator awareness

Prevention Measures:

- Operator training: Emphasize safe operating procedures, hazard awareness, and defensive driving techniques

- Regular Inspections: Conduct pre-operational inspections to identify and address any mechanical issues

- Proper maintenance: Ensure the jack is properly maintained and in good working order

- Clear aisles and work areas: Maintain a clear and organized work environment to minimize the risk of collisions