32-HR Rigging Supervisor

Course Duration

32 Hours

Course Session

4-5 Session

Language

English, Spanish

Training Type

Classroom Training

Course Overview

This 32 hour rigging training course will provide individuals with a strong understanding on how to supervise and coordinate rigging crews and rigging equipment setup. An emphasis will be placed on proper rigging techniques, how to inspect rigging equipment, proper load amounts, how to calculate the center of gravity to apply proper rigging hitches and OSHA and DOB regulations.

This advanced training program is designed for individuals responsible for overseeing and managing rigging operations in construction, industrial, and other relevant settings. This comprehensive program aims to equip supervisors with the in-depth knowledge, skills, and understanding to ensure safe, efficient, and compliant rigging practices.

Fast Line Safety Training delivers high-quality, hands-on training at your location and provides the industry’s preferred operator card.

Additional Course Information

What you'll learn

- Rigging Principles and Techniques

- Rigging Equipment

- Crane and Hoist Operations

- Hazards Identification and Risk Assessment

- Planning and Supervision

- OSHA Regulations and Industry Standards

- Leadership and Communication Skills

CEU Credits Earned

3.2

Continuous Education Units

Need to renew your 32 hour Rigging Worker?

You may need to renew your 16-Hour Rigging Worker certification if:

- Your current certification has expired

- Your employer requires it;

- Industry standards or regulations have changed

- If you feel that your skills need a refresher

Learning Outcomes

Upon completion of this course, students should be able to:

- Understand hazards relating to rigging and how to prevent them

- Understand how to inspect rigging equipment in compliance with OSHA and ASME standards

- Identify equipment capacities, hitch configurations, and basic knots

- Calculate the weight of loads to find the center of gravity

- Understand signaling used during rigging operations

Interested in becoming a Rigging Supervisor?

Course Outline

This Course outline provides a general overview of the topics to be covered. The actual course content may be adjusted slightly based on the specific needs and learning styles of the participants

Lesson 1: Introduction to Cranes and Derricks

- Instruction on inspection

- Maintenance

- Repair

- Use

- Installation

- Hazards associated with the relevant sections of the Building

Code - Industry practice with regard to rigging

Lesson 2: Crane and Rigging incidents

- Common causes of incidents with cranes and rigging

- Historical crane and rigging incidents in NYC and other

major cities - Overview of rigging incident statistics for the most current

24-month period:- Failure

- Injury

- Death

- A close review of two failure scenarios with emphasis on what

went wrong and how the incident could have been prev

Lesson 3: CFR 29 OSHA 1926 Overview

- Subpart CC(Cranes and Derrick in Construction)

Lesson 4: NYC Code Review

- Codes

- Rules

- Related Department policy statements

- Regulatory notices

- Bulletins and Memos

- Including: 2022 Building Code

- Chapter 33

- 1 RCNY 3316-01

- 1 RCNY 3319-01

- 1 RCNY 3319-01

- Chapter 33

- Including: 2022 Building Code

Lesson 5: NYC Department of Buildings

- Administrative standard operating procedures

- Permits

- Department notifications

- Forms

- Filing and site documents

- Plans

- Inspection checklists/logs

- Wind and weather advisories

Lesson 6: NYC Department of Transportation (DOT)

- Codes

- Rules

- Regulations

- Operating procedures

- Policy and procedures

- Permits/notifications

- Forms

- Filing and site documents

- Plans, etc.

Lesson 7: NYC Transit Authority (NYCTA)

- Codes

- Rules

- Regulations

- Operating procedures

- Policy and procedures

- Permits/notifications

- Forms

- Filing and site documents

- Plans, etc

Lesson 8: Basic Building Structure

- Structural framing

- Floor framing

- Roof framing

- Exterior envelope

- Roof parapet

- Masonry walls columns

- Concrete slabs

- Walls and columns

- Special emphasis on building structures traditionally

used to support rigging equipment- Floors

- Exterior walls, bearing and non-bearing

- Parapets

- Roof dunnage

- Structural steel beams and columns

Lesson 9: Inspection of Cranes and Ropes

- Periodic/annual inspection performed by owner, the Department of Buildings and documentation to be maintained

- Frequent inspection, who can perform and

documentation to be maintained - How to perform a frequent inspection

- Components inspected during a frequent inspection and how to identify hazards

- Steps to take if hazard discovered inspection process, and safety checklists including:

- What to inspect

- How to inspect

- How frequently to inspect, including

- Rigging systems and anchorage

- Individual components:

- Slings, hoists, mortars, etc.

- Identification of wear, defects, failure signs in all

rigging equipment - Handling, maintenance, repair/replacement of rigging equipment, rope, hardware, etc., rope (wire and fiber) and hardware used in rigging, type, strength, application, manufacturers’ specifications and limitations, handling

- Connection and termination of wire/fiber rope

(fasteners, knots, hitches, hooks, shackles, thimbles, eyes, tackle blocks, etc.) including connection to suspended work platforms, (i.e., scaffold platforms); hoist loads (materials, equipment).

Lesson 10: Maintenance and Repair of Cranes and Ropes

- Types of maintenance required

- Who can maintain cranes

- Who can repair a crane

- Safeguards before beginning maintenance or repairs

Lesson 11: Crane Setup

- Ground conditions

- Deviation from plans not permitted

- Founding of crane, outrigger placement and cribbing

- Danger to underground infrastructure, excavations,

foundations, etc

Lesson 12: Reading Plans

Lesson 13: Site Precautions

- Hazards of operating in a dense urban environment

- High wind hazards

- Operating near power lines

- Prohibition against hoisting over pedestrians, traffic, and adjoining buildings

- Requirements for shutting down and securing the crane

- Communication between workers and supervisors while rigging radios, hand signals, flags, etc.

Lesson 14: Reading Load Charts

NYC-approved load charts

Lesson 15: Signaling

Communication between workers & supervisors while rigging:

- Radios

- Hand signals

- Flags

- etc.

Lesson 16: Lifting and Lowering Loads

- Weights and materials

- Center of gravity

- Rigging requirements

- Critical picks

- Logs and record keeping, including:

- Maintenance records for equipment

- Pre-task and safety meetings

- Hoisting and hoist equipment (manual, electric, etc.)

- Pulley, block/tackle, sheaves, drums, slings (all types), chains, electric hoist motors

- Capacity

- Rigging of motors

- Mechanical/electrical safety devices and

- Operation

- Critical picks

- Construction and use

- Suspended working platforms, manufacturer’s

specifications, limitations, max spans, guardrails,

planking, debris netting, stirrups, maneuvering, drifting, securing of platform during and end of shift; suspension methods, slings, c-hooks, outrigger beams, clamps, counterweights, shoring scaffolds (outrigger supports),

masonry and concrete anchors (expansion, adhesive, screw) - Pull testing of anchorage devices. Off-the-shelf

hardware, as well as site-built hardware systems must be included

Lesson 17: Operational Aids and Safety Devices

- Types of aids, safety devices, functions, how to use, steps to take if operational aid/safety device not working. Acceptable means to substitute for a malfunctioning aid/safety device Personal fall-arrest systems, use, storage, maintenance, installation, and anchorage

Lesson 18: PPE

- Personal fall arrest systems use, storage, maintenance, installation, and anchorage

- Other Types of personal protection (hard hats, respirators, gloves, shoes, eye protection, clothing)

Lesson 19: Crane and Derrick Safety Protocols and Emergency Procedures

- Electrical safety during rigging installation and use, including work performed from suspended working decks (welding, use of electrical equipment, etc.).

- Overhead protection/safety exclusion zones during rigging, hoisting, and use of scaffolding

- Sidewalk sheds, barriers, flag persons, hazard signage.

Lesson 20: Crane Assembly, Jumping and Disassembly

Lesson 21: Rigging Requirements

- Definition of rigging such as the traditional uses for rigging in the construction and industrial environment, including industrial rope access (IRA).

- Mathematics of rigging, measurement, symbols,

geometry, calculations, leverage, friction, fulcrum, center of gravity, uniform and concentrated loading. - Wind effects on netting and other components.

- Calculation of weight, loads, sling loads, drifting loads, balance and tipping points of objects, center of gravity, non-symmetrical center of gravity and buoyancy (lifting in water).

Lesson 22: General Construction Site Hazards

Pricing

Group

Minimum 5 person per class-

We Come to You

-

Schedule Flexibility

-

Hands-on Training

Inquire about setting up a private class for your team and ask about group discounts.

To successfully complete the training, students must:

- Earn a minimum score of 75% on the final evaluation.

- Complete 100% of the required course content.

- Completion of required pre-and post-quiz assessment

- Actively participate in all written and practical learning activities.

- Completion of Continuing Education and Training Registration Form

Please note that no make-up time will be provided for missed assignments or activities.

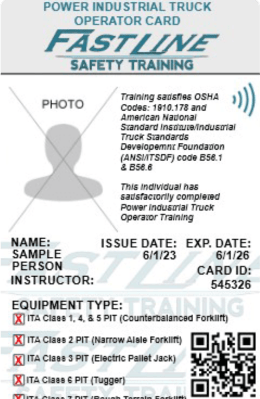

The Preferred Equipment Operator Card

QR Code/ NFC Technology

Digital ID Card: Quickly scan your card with any smartphone camera to experience the convenience of your digital identification profile.

Blockchain Protected

Blockchain-protected: Experience the next generation of security. Leveraging the power of blockchain technology, your cards are encrypted and tamper-proof, ensuring your information is always safe.

ID Cards with Face Photo

Full-resolution ID Cards: Fast Line Safety Training issues A standard identification card featuring a full-color photograph of the individual.

Completion cards are valid for 3 years and in all 50 states.

We are the only providers issuing such permanent cards.

Book your next training course with us.

Fill out the form below or call us at (631) 393 – 6755

to set up your training session!

l out the form below or

call us at (631) 393 – 6755

to set up your training session!

Frequently Asked Questions

Who should take this 32 Hour Rigging Supervisor course?

- Rigging foremen

- Site supervisors

- Project managers

- Safety managers

- Anyone responsible for planning and overseeing rigging operations

What are the prerequisites for the course?

- Prior experience in the rigging industry is highly recommended

- Some courses may require a valid 16-hour Rigging Worker certification

What is the format of the course?

Typically includes a combination of classroom instruction, hands-on exercises, and simulations

Do I need to bring any equipment to this course?

Check with your instructor regarding any required personal protective equipment (PPE)