Course Duration

30 Hours

Course Session

4-5 Session

Language

English, Spanish

Training Type

Classroom Training

Course Overview

Why is OSHA 30-Hour training necessary? In accordance with the Occupational Safety and Health act of 1970, employers are responsible for ensuring a safe and healthy workplace for their employees.

This training program is a comprehensive review of OSHA procedures, policies, and standards. This course will give students a strong understanding of construction safety and health principles as well as place an emphasis on the most hazardous areas using OSHA standards and regulations as a guideline.

Students will learn to locate and identify OSHA standards in 29 CFR, identify causes of accidents and fatalities in hazardous areas within the worksite while providing abatement technique suggestions for these hazards, and learn to understand most construction processes, materials, and equipment.

Fast Line Safety Training delivers high-quality, hands-on training at your location and provides the industry’s preferred operator card.

***Upon successful completion of the course, students will receive a certificate of completion and a permanent card within two to three weeks.***

Additional Course Information

What you'll learn

- Hazard Recognition

- Accident Prevention

- OSHA Standards

- Personal Protective Equipment (PPE)

- Emergency Response Procedures

- Recordkeeping

CEU Credits Earned

3.0

Continuous Education Units

Who Needs OSHA 30-Hour Training?

OSHA-30 training is specifically designed for supervisors and workers with safety responsibilities in various industries. It’s more in-depth than the OSHA 10 courses and covers a wider range of safety and health topics.

Here are some of the types of workers who need this OSHA 30 Training:

- Construction Supervisors

- Foremen

- Project Managers

- Safety Managers

- Any worker with safety oversight responsibilities on construction sites.

Remember: If you’re unsure whether you need this OSHA 30 training, it’s always best to consult with your employer or a safety professional. They can assess your job duties and responsibilities to determine the appropriate level of training for you.

Learning Outcomes

- Recognize worker rights and an employer’s responsibility to the employee under OSHA

- Identify how to select the appropriate personal protective equipment (PPE) and life-saving equipment

- Discuss risks they may be associated with improper use of scaffolding equipment

- Define different control methods for controlling the four main health hazards that construction workers may be exposed to

- Explain the principles for at least three protective systems that are used while working in and around excavations

- Explain the differences between the 5 classes of fires and discuss the solutions for extinguishing them

NYC DOB Requirements: OSHA 30-Hour Training

Local Law 196 introduced new regulations for demolition and construction workers employed in the 5 boroughs of New York City that will require them to have a specific amount of training. Workers are now required to have a minimum of 30 Hours of training and supervisors will be required to have a minimum of 62 hours of training by December 1st, 2019. In addition to the required amount of training individuals will also need to acquire the appropriate Site Safety Training (SST) card to prove they have completed the necessary training.

Course Outline

Lesson 1: Introduction to OSHA - 45 Minutes

This section will review worker rights, employer responsibilities, and how to file a complaint. Some additional areas which will be covered during the introduction to OSHA are material safety data sheets, OSHA form 300, and fatality and injury statistics

Lesson 2: Managing Safety and Health - 2 Hours

Managing safety and health will include information on illness prevention programs, accident prevention programs, inspections performed on jobsites, analysis of jobsites, how to prevent and avoid hazardous situations, and pre-task safety meetings among other things.

Lesson 3: OSHA focus four hazards - 4 Hours

OSHA has linked the majority of fatalities in the construction industry to one of the 4 types of hazards listed below (Focus Four Hazards). These 4 hazards are the leading cause of fatalities on construction sites with falls being the most common.

- Falls (minimum one hour and 15 minutes)

- Electrocution

- Struck-By (e.g., falling objects, trucks, cranes)

- Caught-In or Between (e.g., trench hazards, equipment)

Lesson 4: Personal Protective and Lifesaving Equipment - 2 Hours

A review of personal protective equipment and proper work practices while using PPE

Lesson 5: Health Hazards in Construciton - 2 hours

Review some of the common health hazards in construction including but not limited to respirable crystalline silica and noise hazards.

Lesson 6: Stairways and Ladders - 1 Hour

Will cover general requirements that must be followed when work is performed using stairways and ladders.

Lesson 7: Electives - 12 Hours

The instructor is required to teach at least 6 of the following topics listed below:

- Concrete and Masonry Construction

- Confined Space Entry

- Cranes, Derricks, Hoists, Elevators, & Conveyors

- Ergonomics

- Excavations

- Fire Protection and Prevention

- Materials Handling, Storage, Use and Disposal

- Motor Vehicles, Mechanized Equipment and Marine Operations; Rollover Protective Structures and Overhead Protection; and Signs, Signals and Barricades

- Powered Industrial Vehicles

- Safety and Health Programs

- Scaffolds

- Steel Erection

- Tools – Hand and Power

- Welding and Cutting

Pricing

Group

Minimum 5 person per class-

We Come to You

-

Schedule Flexibility

-

Hands-on Training

Inquire about setting up a private class for your team and ask about group discounts.

To successfully complete the training, students must:

- Earn a minimum score of 75% on the final evaluation.

- Complete 100% of the required course content.

- Completion of required pre-and post-quiz assessment

- Actively participate in all written and practical learning activities.

- Completion of Continuing Education and Training Registration Form

Please note that no make-up time will be provided for missed assignments or activities.

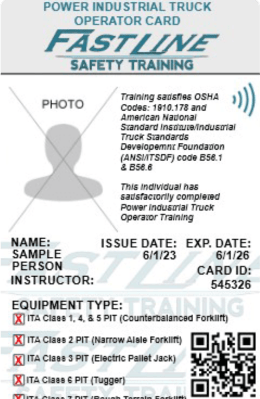

The Preferred Equipment Operator Card

QR Code/ NFC Technology

Digital ID Card: Quickly scan your card with any smartphone camera to experience the convenience of your digital identification profile.

Blockchain Protected

Blockchain-protected: Experience the next generation of security. Leveraging the power of blockchain technology, your cards are encrypted and tamper-proof, ensuring your information is always safe.

ID Cards with Face Photo

Full-resolution ID Cards: Fast Line Safety Training issues A standard identification card featuring a full-color photograph of the individual.

Completion cards are valid for 3 years and in all 50 states.

We are the only providers issuing such permanent cards.

Book your next training course with us.

Fill out the form below or call us at (631) 393 – 6755

to set up your training session!

l out the form below or

call us at (631) 393 – 6755

to set up your training session!

Frequently Asked Questions

What are the key benefits of completing the OSHA 30-Hour Training?

- Increased awareness of workplace hazards

- Improved ability to prevent accidents and injuries

- Enhanced ability to comply with OSHA regulations

- Increased confidence and competence in promoting a safe work environment

- Potential for career advancement opportunities

Will this training help me prevent injuries at work?

Absolutely! The OSHA 30-Hour Training provides you with the knowledge and tools to identify and control workplace hazards, minimizing the risk of accidents and injuries.

How does this training benefit my employer?

A well-trained workforce leads to a safer and more productive work environment. Benefits for your employer include:

- Reduced workplace injuries and illnesses

- Improved employee morale and retention

- Increased productivity and efficiency

- Lower workers’ compensation costs

- Enhanced company reputation for safety and compliance