NJ Rough Terrain Forklift Training & Certification

Course Duration

4 Hours

Course Session

1 Session

Language

English, Spanish

Training Type

Onsite Training

Course Overview

Our Rough Terrain Forklift training course curriculum combines a plethora of training, such as formal instruction, practical training and learning, and assessing the operators performance in the workplace and with equipment.

This only covers Rough Terrain Forklift, however, Fast Line Safety Training also offers a complete Powered Industrial Truck Course that combines the below trainings into one course:

Fast Line Safety Training delivers high-quality, hands-on training at your location and provides the industry’s preferred operator card.

Powered Industrial Truck (P.I.T.) Training Program

- Counterbalance ForkliftClass 1, 4, & 5

- Stand-up Narrow Aisle ForkliftClass 2

- Electric Pallet JackClass 3

- Rough Terrain ForkliftClass 7

Additional Course Information

What you'll learn

- Safe operating procedures

- Terrain awareness

- Load stability and weight limits

- Pre-operational inspections

- Emergency Procedures

- Traffic and pedestrian safety

- Understanding rough terrain forklift components

- Proper lifting techniques

This Training is valid for:

3 Years

Retraining is essential to ensure that operator’s skills remain updated, and they continue to operate forklifts safely and efficiently.

Who Needs Rough Terrain Forklift Training & Certification?

Individuals who operate forklifts in environments with natural or uneven terrains, such as lumber yards, construction sites, and land moving projects, require Rough Terrain Forklift Training. This includes:

- Full-time employees

- Contractors

- Temporary workers who may operate a rough terrain forklift, even occasionally.

Learning Outcomes for Rough Terrain Forklift Certification

Upon successful completion of this training, participants will be able to operate rough terrain forklifts safely and efficiently in accordance with relevant regulations and company policies.

- Understand relevant OSHA, state, and company safety regulations

- Differentiate between Class 7 and other hazard recognition

- Describe pre-shift inspections, safe lifting/lowering, and travel techniques

- Navigate inclines, declines, and uneven terrain safely

- Identify and avoid potential hazards in the workplace

- Demonstrate a commitment to safety and focus on preventing accidents

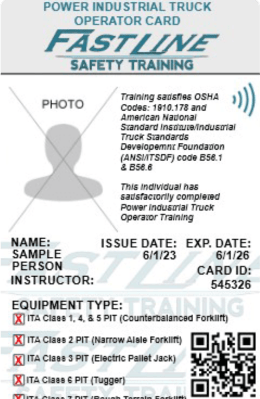

Advanced Rough Terrain Forklift Certification with Fast Line Safety Training

At Fast Line Safety Training, we take pride in offering an advanced Rough Terrain Forklift Certification that goes beyond the conventional. Our certification program is not just about meeting the necessary legal requirements; it’s about equipping operators with cutting-edge tools and technologies for real-world operational verification and efficiency

One of the standout features of our advanced certification is the issuance of NFC-enabled ID cards upon successful completion of the course. These cards, which are valid for three years and recognized nationwide, revolutionize the verification process.

With a simple tap or proximity of a smartphone to the NFC chip embedded in the card, instant verification of training is achieved. This eliminates the need for cumbersome paperwork or manual checks, streamlining the process and enhancing operational efficiency.

Choosing Fast Line’s Advanced Rough Terrain Forklift Certification means stepping into the future of operational safety and efficiency. Our NFC-enabled cards represent our commitment to innovation, ensuring that your team is always ready, verifiable, and compliant with the latest in safety training technology.

By opting for our advanced certification, you are ensuring that your team is not just trained but is also equipped with the latest tools to make verification and compliance as seamless as possible.

Live on one of these states? We Travel To You!

Fast Line Safety Training is proud to offer this certification across New York, New Jersey and Pennsylvania. Explore the links below to discover more about this certification in other areas:

Course Outline

This Course outline provides a general overview of the topics to be covered. The actual course content may be adjusted slightly based on the specific needs and learning styles of the participants

Lesson 1: Introduction & Fundamentals

- What is a Powered Industrial Truck (PIT)

- Definition and classifications (Class 7)

- Common uses of rough terrain forklifts

- Federal and State Regulations

- OSHA standards for forklift operation

- Relevant state regulations

- Company, Site, & Manufacturer Requirements

- Company safety policies and procedures

- Site-specific rules and restrictions

- Forklift manufacturer guidelines

- Risk Factors and Statistics

- Common forklift accidents and injuries

- Statistics on forklift accidents

Lesson 2: Rough Terrain Forklift Specifics

- Characteristics of Rough Terrain Forklifts

- Design features and capabilities

- Terrain handling and stability

- Attachments and their uses

- Outriggers

- Purpose and operation

- Safety considerations

- Steering Modes

- Crab steering and other steering options

- Tires

- Tire types and maintenance

Lesson 3: Center of Gravity and Load Handling

- Center of Gravity Concepts

- Combined center of gravity

- Centrifugal force

- Inertia

- Load Chart

- Reading and interpreting load charts

- Calculating load center

- Picking Up a Load

- Approach and positioning

- Lifting techniques

- Traveling with a Load

- Safe travel paths and speeds

- Maneuvering in tight spaces

Lesson 4: Placing a Load and Other Procedures

- Placing a Load

- Accurate placement and lowering

- Stacking and unstacking procedures

- Ramp Procedures

- Safe operation on inclines and declines

- Dock Procedures

- Loading and unloading from docks

- Energized Power Lines

- Hazard awareness and avoidance

- Refueling Process

- Safe refueling procedures for diesel/gasoline/CNG

Lesson 5: General Safety Practices

- Operator Daily Checklist

- Pre-shift inspection of the forklift

- Safety Devices

- Seat belts, back-up alarms, horns, etc.

- Approved PIT Attachments

- Using attachments safely

- Forks

- Proper fork selection and maintenance

- Facility Characteristics

- Awareness of hazards and obstacles

- Intersection Procedures

- Crossing paths with pedestrians and other vehicles

- Safe Travel Rules

- Maintaining a safe following distance

- Avoiding blind spots

Lesson 6: Emergency Procedures and Wrap-Up

- Emergency Stops / Braking

- Proper braking techniques

- Emergency procedures in case of accidents

- Don’t Leave Your PIT Unattended

- Secure the forklift properly

- Safe Parking Rules

- Designated parking areas

- 3-Point Contact rule

- Important Review

- Key takeaways and safety reminders

- Certification and Testing

- Operator evaluation and certification process

Pricing

Group

Minimum 5 person per class-

We Come to You

-

Schedule Flexibility

-

Hands-on Training

Inquire about setting up a private class for your team and ask about group discounts.

To successfully complete the training, students must:

- Earn a minimum score of 75% on the final evaluation.

- Complete 100% of the required course content.

- Completion of required pre-and post-quiz assessment

- Actively participate in all written and practical learning activities.

- Completion of Continuing Education and Training Registration Form

Please note that no make-up time will be provided for missed assignments or activities.

The Preferred Equipment Operator Card

QR Code/ NFC Technology

Digital ID Card: Quickly scan your card with any smartphone camera to experience the convenience of your digital identification profile.

Blockchain Protected

Blockchain-protected: Experience the next generation of security. Leveraging the power of blockchain technology, your cards are encrypted and tamper-proof, ensuring your information is always safe.

ID Cards with Face Photo

Full-resolution ID Cards: Fast Line Safety Training issues A standard identification card featuring a full-color photograph of the individual.

Completion cards are valid for 3 years and in all 50 states.

We are the only providers issuing such permanent cards.

Book your next training course with us.

Fill out the form below or call us at (201) 208 – 2203

to set up your training session!

l out the form below or

call us at (631) 393 – 6755

to set up your training session!

Frequently Asked Questions

What is Rough Terrain Forklift Training?

- Precautions and Safety: Learning essential safety measures and precautions for operating rough terrain forklifts.

- Forklift Inspection: Understanding how to efficiently inspect the forklift to ensure it’s properly working.

- Operational Techniques: Gaining practical knowledge and skills to safely operate rough terrain forklifts, considering their stability and limitations.

What are the key differences between operating a rough terrain forklift and other types of forklifts?

- Terrain capability: Rough terrain forklifts are specifically designed to operate on uneven and challenging surfaces like construction sites, outdoor yards, and off-road environments.

- Maneuverability: They often have larger tires and enhanced ground clearance for better traction and stability on uneven terrain.

- Stability: Features like counterweights and wider wheelbases help maintain stability on inclines and declines.

- Visibility: Operators may need to be more aware of their surroundings and potential hazards due to varying terrain and limited visibility.

What are the common causes of rough terrain forklift accidents, and how can they be prevented?

Common Accident Causes

- Speeding: Operating the forklift too quickly, especially on uneven terrain, can lead to loss of control.

- Improper loading: Overloading the forklift or improperly loading the pallet can cause instability and tipping.

- Distractions: Distractions such as talking on a phone or texting can impair operator awareness.

- Lack of training: Inadequate training on operating in challenging terrain and recognizing specific hazards.

- Poor visibility: Operating in low-light conditions or areas with limited visibility.

Prevention measures:

- Operator training: Emphasize safe operating procedures for rough terrain conditions, hazard awareness, and defensive driving techniques.

- Pre-operational inspections: Conduct thorough pre-operational inspections to identify and address any mechanical issues.

- Proper maintenance: Ensure the forklift is properly maintained and in good working order.

- Clear work areas: Maintain a clear and organized work area to minimize the risk of collisions.

- Use of spotters: If visibility is limited, use a spotter to guide the operator.

What specific safety features should I look for in Rough Terrain forklift?

- Enhanced visibility: Features like improved lighting, panoramic windows, and rearview cameras can significantly improve operator visibility.

- Stability aids: Features like automatic grade sensing, anti-slip differentials, and automatic braking systems can help maintain stability on inclines and declines.

- Rollover protection structures (ROPS): Ensure the ROPS is in good condition and provides adequate protection in the event of a rollover.

- Seat belts: Always use seat belts when operating a rough terrain forklift.

- Operator presence system: Requires the operator to be in a designated position for the forklift to operate.