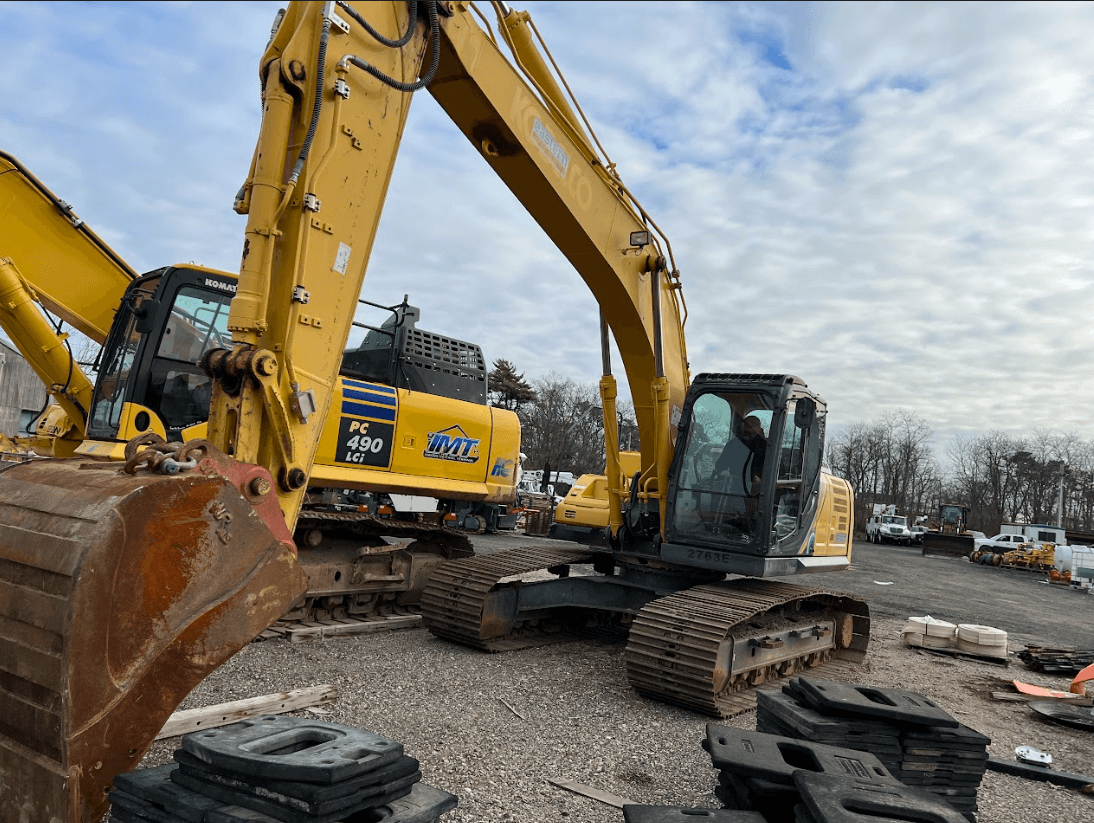

PA Excavator Certification & Training

Course Duration

4 Hours

Course Session

1 Session

Language

English, Spanish

Training Type

Onsite Training

Course Overview

Our Excavator Training covers the safe use and operation of Large and Mini Exacavators, as required by OSHA, Mine Safety & Health Administration (MSHA), International Organization for Standardization (ISO), Society of Automotive Engineering (SAE), and American National Standards Institute (ANSI). The course curriculum combines a plethora of training, such as formal instruction, practical training and learning, and assessing the operators performance in the workplace and with the equipment.

Fast Line Safety Training delivers high-quality, hands-on training at your location and provides the industry’s preferred operator card.

Dirt Moving Training Package

Additional Course Information

What you'll learn

- Safe operating procedures

- Pre-operational inspections

- Proper attachment selection and use

- Maneuvering and control techniques

- Digging and trenching techniques

- Material handling and loading

- Safety regulations and best practices

- Emergency procedures

This Training is valid for:

3 Years

Retraining is essential to ensure that operator’s skills remain updated, and they continue to operate forklifts safely and efficiently.

Why Do I Need Excavator Certification?

- Ensures Safety: Proper training minimizes the risk of accidents on construction sites.

- Boosts Employment Opportunities: Certified Operators are preferred by employers for their verified skills.

- Meets Legal requirements: Many regions mandate certification for operating heavy machinery

- Enhances Efficiency Certified Operators can complete tasks more efficiently, saving time and resources

Learning Outcomes

Upon completion, participants will be able to:

- Understand the basic components and operating principles of a large excavator.

- Perform pre-operational inspections and identify potential hazards.

- Operate a large excavator safely and efficiently in various conditions.

- Utilize attachments safely and effectively.

- Practice safe loading and unloading procedures.

- Follow lockout/tagout procedures for maintenance.

- Understand and apply relevant safety regulations.

Which Excavator Training Should I Choose?

Our excavator training, covering both mini and large excavators, is comprehensive yet concise. The course spans a single session lasting 4 hours, ensuring you’re well-equipped to operate both types of excavators safely and efficiently.

Large Excavator vs. Mini Excavator Training

Large Excavator Training:

- Heavy-Duty Operations: Learn to handle large-scale digging, trenching, and lifting tasks.

- Control Mastery: Understand the nuances of operating larger machinery with precision.

- Terrain Challenges: Train to navigate and operate on challenging terrains typical for large excavators.

Mini Excavator Training:

- Compact Operations: Master the skills needed for tasks in confined spaces.

- Agility and Precision: Mini excavators require a different set of operational skills, focusing on agility.

- Versatility: Learn the diverse applications of mini excavators, from digging to drilling.

Live on one of these states? We Travel To You!

Fast Line Safety Training is proud to offer this certification across New York, New Jersey and Pennsylvania. Explore the links below to discover more about this certification in other areas:

Course Outline

This Course outline provides a general overview of the topics to be covered. The actual course content may be adjusted slightly based on the specific needs and learning styles of the participants

Lesson 1: Introduction & Safety Fundamentals

- Course Overview & Introduction

- Course objectives and expectations

- Importance of safety in excavator operation

- Safety Regulations & Standards

- OSHA regulations and industry best practices

- Review of state-specific regulations (if applicable)

- Personal Protective Equipment (PPE)

- Importance and types of PPE required (e.g., helmets, gloves, safety glasses)

- Proper fit and usage of PPE

- Hazard Identification & Risk Assessment

- Identifying potential hazards around the job site

- Performing a Job Safety Analysis (JSA)

Lesson 2: Excavator Components & Operation

- Excavator Types

- Crawler excavators vs. wheeled excavators

- Different sizes and configurations

- Common attachments and their uses

- Components & Controls

- Identifying key components (engine, hydraulics, controls)

- Understanding the function of each control lever/pedal

- Basic Operation & Maneuvering

- Starting and stopping the engine

- Moving the excavator forward, reverse, and sideways

- Controlling travel speed and direction

Lesson 3: Attachments & Advanced Maneuvering

- Attachment Safety

- Safe attachment selection and installation procedures

- Using attachments for various tasks (e.g., digging, trenching, loading)

- Understanding the “danger swing area” and avoiding collisions

- Advanced Maneuvering

- Operating on slopes and uneven terrain

- Loading and unloading materials

- Digging trenches and foundations

Lesson 4: Maintenance & Emergency Procedures

- Pre-Operational & Post-Operational Inspections

- Checking fluid levels, track tension, and other critical components

- Identifying and reporting any maintenance issues

- Lockout/Tagout Procedures

- Understanding and applying lockout/tagout procedures for maintenance

- Emergency Procedures

- Responding to rollovers, fires, and other emergencies

- Evacuating the machine safely

Lesson 5: Practical Exercise & Evaluation

- Hands-on Operation

- Participants operate the excavator under instructor supervision

- Practice basic maneuvers, attachment use, and safety procedures

- Evaluation

- Instructor assesses participant performance on safety and operating skills

- Providing feedback and answering questions

Pricing

Group

Minimum 5 person per class-

We Come to You

-

Schedule Flexibility

-

Hands-on Training

Inquire about setting up a private class for your team and ask about group discounts.

To successfully complete the training, students must:

- Earn a minimum score of 75% on the final evaluation.

- Complete 100% of the required course content.

- Completion of required pre-and post-quiz assessment

- Actively participate in all written and practical learning activities.

- Completion of Continuing Education and Training Registration Form

Please note that no make-up time will be provided for missed assignments or activities.

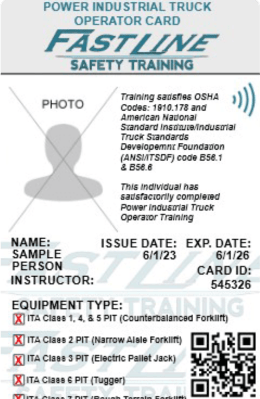

The Preferred Equipment Operator Card

QR Code/ NFC Technology

Digital ID Card: Quickly scan your card with any smartphone camera to experience the convenience of your digital identification profile.

Blockchain Protected

Blockchain-protected: Experience the next generation of security. Leveraging the power of blockchain technology, your cards are encrypted and tamper-proof, ensuring your information is always safe.

ID Cards with Face Photo

Full-resolution ID Cards: Fast Line Safety Training issues A standard identification card featuring a full-color photograph of the individual.

Completion cards are valid for 3 years and in all 50 states.

We are the only providers issuing such permanent cards.

Book your next training course with us.

Fill out the form below or call us at (484) 205 – 9802

to set up your training session!

l out the form below or

call us at (631) 393 – 6755

to set up your training session!

Frequently Asked Questions

What is an excavator, and why is it important to operate it safely?

An excavator is a powerful construction machine used for digging, trenching, and material handling. Safe operation is crucial to prevent accidents, injuries, and property damage.

What types of jobs use excavators?

Excavators are used in a wide range of industries, including construction, landscaping, mining, and demolition.

What safety features are include in modern excavators?

Although online forklift certification programs exist, they must include a hands-on evaluation component. many online training programs do not offer this component and may need to be better as a certification.

How do I maintain my excavator properly?

Proper maintenance is essential for safe and efficient operation. Our course will cover basic maintenance procedures, including checking fluid levels, inspecting tracks/tires, and performing routine inspections.

What are the common causes of excavator accidents?

Common Causes include operator error, improper maintenance, environmental hazards, and equipment malfunctions.

How do I choose the right excavator attachments for my job?

The choice of attachments depends on the specific task you need to perform. Our course will cover different types of attachments and their applications