PA Scissor Lift & Boom Lift Certification and Training

Course Duration

4 Hours

Course Session

1 Session

Language

English, Spanish

Training Type

Onsite Training

Course Overview

Operators must be properly trained to safely use equipment to minimize the risk of injuries, property damage, and worksite liability.

The new ANSI A92 standards were developed to promote the efficiency and safe use of Mobile Elevating Work Platforms, formally known as aerial work platforms.

Anyone qualified under the current standards will not be trained under the new ANSI A92 standards until they undergo additional training. The deadline to meet ANSI A92 standards was June 1, 2020.

Fast Line Safety Training delivers high-quality, hands-on training at your location and provides the industry’s preferred operator card.

Be Advised:

Boom Lift/Scissor Lift (MEWP) training must consist of both a classroom and hands-on portion to comply with the new ANSI A92 standards; online trainings are not compliant.

Additional Course Information

What you'll learn

- Hazard identification

- Risk Assessment

- Emergency procedures

- Safe work practices

- Equipment Operation

- Career Advancement

- Enhanced Safety

- Load Capacity and Stability

- Maintenance

- Pre-operational inspections

This Training is valid for:

3 Years

Retraining is essential to ensure that operator’s skills remain updated, and they continue to operate forklifts safely and efficiently.

Mobile Elevation Work Platform (M.E.W.P.)

Course curriculum combines many training, such as formal instructions, practical training and learning, and assessing the operator’s performance in the workplace and with equipment. Under the ANSI A92 standards, MEWPs are classified differently and are divided into the following groups:

- Group A for those with platforms that move vertically but stay inside the tipping line

- Group B for all other MEWPs – typically, boom-type equipment where the platform extends past the tipping line

Learning Outcomes

Upon Successful completion of this scissor and boom lift training course, participants will be able to:

- Demonstrate a comprehensive understanding of MEWP safety principles and regulations.

- Operate scissor lifts and boom lifts safely and efficiently per OSHA and other relevant standards.

- Recognize and respond appropriately to potential hazards and emergencies.

- Contribute to a safe and productive work environment.

Benefits of Training With Fast Line Safety Training

Our training offers more than just compliance with OSHA standards. Here’s what our program covers:

- Safe operation of scissor lifts under various conditions.

- Identification and use of lift controls.

- Navigating around obstacles and pedestrians.

- Handling scissor lifts on different terrains.

- Loading, moving, and unloading cargo.

- Routine maintenance and inspections.

- Hazard assessment in the surrounding environment.

Untrained or improperly trained workers can lead to accidents, resulting in property damage, equipment damage, or even severe injuries. It’s illegal for employers to let workers operate scissor lifts without proper certification. With our training, you can avoid expensive fines, penalties, and potential litigation.

Mobile Elevating Work Platform (MEWP) Operator Training

- Manual Vertical (1A)

- Bucket Truck (1B)

- Scissor and Vertical Lift (3A)

- Boom Lift (3B)

Understanding the new ANSI A92 Standards

The ANSI A92 standards are not just a set of arbitrary rules. They provide comprehensive criteria for various aerial work platforms. This includes vehicle-mounted rotating and elevating work platforms, elevating aerial platforms, and boom-supported elevated aerial platforms. By adhering to these standards, companies ensure the safety of their workers and the efficiency of their operations. Anyone seeking scissor lift certification or boom lift certification should be well-versed in these standards.

Live on one of these states? We Travel To You!

Fast Line Safety Training is proud to offer this certification across New York, New Jersey and Pennsylvania. Explore the links below to discover more about this certification in other areas:

Course Outline

This Course outline provides a general overview of the topics to be covered. The actual course content may be adjusted slightly based on the specific needs and learning styles of the participants

Lesson 1: Introduction & Regulations

- Define and classify Mobile Elevating Work Platforms (MEWPs).

- Identify and explain relevant OSHA and other regulatory requirements.

- Understand company, site, and manufacturer-specific MEWP operating procedures.

Lesson 2: Understanding Stability & Loads

- Explain the concept of center of gravity and its impact on MEWP stability.

- Describe how factors like wind, ground conditions, and load distribution affect stability.

- Determine safe load capacities and use load charts correctly.

Lesson 3: Pre-Operational Checks & Safety Features

- Conduct thorough pre-operational inspections of a MEWP.

- Identify and report any safety hazards or equipment malfunctions.

- Understand the importance and procedures for annual and frequent inspections.

Lesson 4: Safe Operation Techniques

- Differentiate between articulated and telescopic boom lifts and their applications.

- Operate extendable axles safely and effectively.

- Conduct proper tire and track inspections.

- Drive and maneuver a MEWP safely and efficiently.

- Operate the turret rotation function safely.

Lesson 5: Special Consideration & Emergencies

- Identify and avoid energized power lines.

- Understand and adhere to wind speed restrictions.

- Use pothole protectors correctly to protect the MEWP.

- Properly deploy and retract outriggers.

- Understand the use and limitations of approved MEWP attachments.

- Follow safe loading and unloading procedures for truck trailers.

Lesson 6: Maintenance & Refueling

- Handle different power sources (electric, diesel, propane) safely.

- Follow safe refueling procedures for propane-powered MEWPs.

- Charge and handle batteries safely.

Lesson 7: Safety Procedures & Emergency Responses

- Identify and avoid common safety violations.

- Maintain awareness of pedestrians and other workers.

- Prevent entanglement hazards.

- Understand the limitations of MEWPs and avoid misuse.

- Understand the potential consequences of accidents.

- Follow safe parking and shutdown procedures.

- Perform safe entry and exit procedures from the platform.

- Understand emergency rescue procedures.

- Operate the auxiliary/emergency lowering system correctly.

Lesson 8: Review & Testing

- Summarize key safety concepts and practices related to MEWP operation.

- Successfully pass a written or practical test demonstrating understanding of MEWP safety principles.

Pricing

Group

Minimum 5 person per class-

We Come to You

-

Schedule Flexibility

-

Hands-on Training

Inquire about setting up a private class for your team and ask about group discounts.

To successfully complete the training, students must:

- Earn a minimum score of 75% on the final evaluation.

- Complete 100% of the required course content.

- Completion of required pre-and post-quiz assessment

- Actively participate in all written and practical learning activities.

- Completion of Continuing Education and Training Registration Form

Please note that no make-up time will be provided for missed assignments or activities.

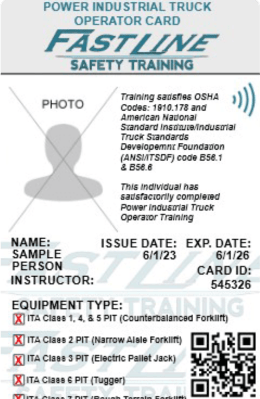

The Preferred Equipment Operator Card

QR Code/ NFC Technology

Digital ID Card: Quickly scan your card with any smartphone camera to experience the convenience of your digital identification profile.

Blockchain Protected

Blockchain-protected: Experience the next generation of security. Leveraging the power of blockchain technology, your cards are encrypted and tamper-proof, ensuring your information is always safe.

ID Cards with Face Photo

Full-resolution ID Cards: Fast Line Safety Training issues A standard identification card featuring a full-color photograph of the individual.

Completion cards are valid for 3 years and in all 50 states.

We are the only providers issuing such permanent cards.

Book your next training course with us.

Fill out the form below or call us at (484) 205 – 9802

to set up your training session!

l out the form below or

call us at (631) 393 – 6755

to set up your training session!

Frequently Asked Questions

What are the differences between scissor lifts and boom lifts?

- Scissor lifts: These lifts have a platform that raises and lowers vertically using a scissor mechanism. They are primarily used for reaching heights within a limited vertical range, often indoors.

- Boom lifts: These lifts have a telescopic or articulating arm that can reach higher heights and often provide greater horizontal reach. They are commonly used for outdoor work, such as tree trimming or construction.

Are both scissor lifts and boom lifts covered in this training?

A: Yes, our comprehensive training program covers both scissor lifts and boom lifts, including their specific safety procedures and operating techniques.

What are some common causes of aerial lift accidents?

A: Common causes of aerial lift accidents include:

- Electrocution: Contact with overhead power lines.

- Tip-overs: Improper setup, overloading, or driving on uneven ground.

- Falls: Falling from the platform or from the ground while accessing the platform.

- Collisions: Striking objects or other vehicles.

- Entrapment: Being crushed between the lift and another object.

What safety equipment is required when operating aerial lifts?

A: Essential safety equipment includes:

- Hard hat: Protects the head from falling objects.

- Safety harness: Prevents falls from the platform.

- Eye protection: Protects the eyes from debris and flying objects.

- Gloves: Protect hands from injuries.

- Proper footwear: Provides good traction and support.